Can the modular connection of the aluminum electrical compact busbar improve the expansion flexibility of the power distribution system?

Release Time : 2025-07-22

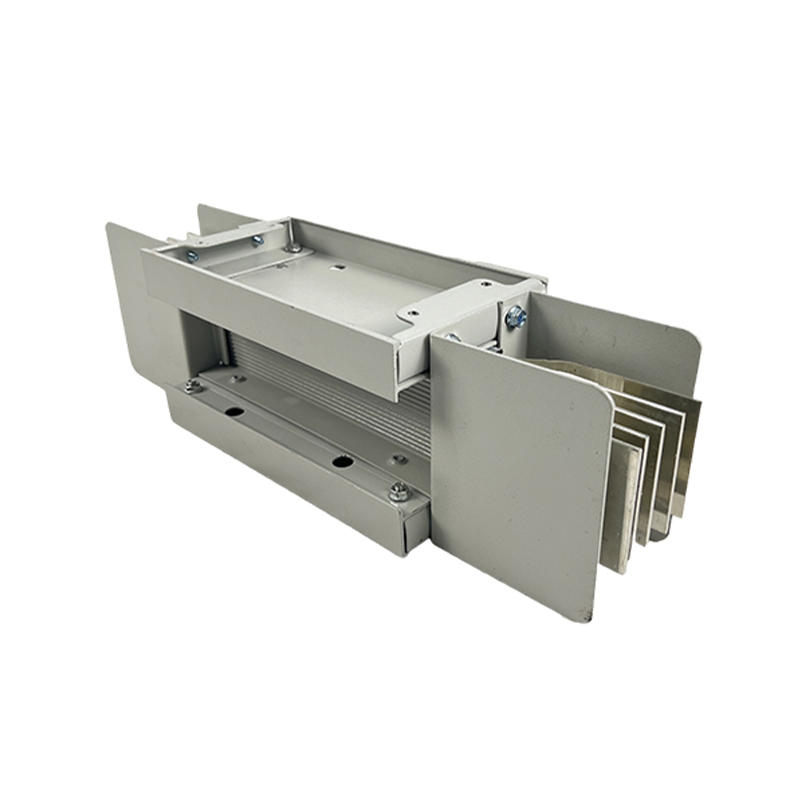

The modular connection of aluminum electrical compact busbar provides the basic conditions for the expansion of the power distribution system from the perspective of structural design. The core is to divide the busbar into standardized unit modules. The interface specifications of each module are unified. Whether it is a straight section, elbow or branch unit, it can be quickly connected through a unified connection component. This standardized design breaks the limitation that traditional busbars require customized connections. When the system needs to be expanded, there is no need to redesign the connection structure. Just select matching modules for combination, which greatly reduces the technical threshold for expansion and makes the expansion process simpler and more efficient.

The plug-and-play feature of modular connection can significantly shorten the expansion period of the power distribution system. Traditional busbar expansion often requires professionals to perform complex wiring and fixing, which is time-consuming and error-prone. The modules of aluminum electrical compact busbar can be installed in a short time through quick connection methods such as buckles and bolts. For example, when the factory production line is expanded, the new equipment needs to be connected to the power distribution system. The technicians only need to connect the new busbar module to the original system and tighten the fixings to complete the circuit conduction. The whole process may only take a few hours, avoiding the days of downtime waiting in traditional expansion methods and reducing the impact on production progress.

For scenarios where the distribution nodes need to be adjusted flexibly, the advantages of modular connection are particularly prominent. In large shopping malls, office buildings and other places, the distribution points may need to be changed frequently as the functional areas are adjusted. The modules of aluminum electrical compact busbar are firmly connected and removable. If you need to move the branch unit position, you only need to loosen the connection components, adjust the module position and re-fix it without damaging the busbar body. This removable feature allows the distribution system to change flexibly according to the use needs, avoiding the problem of destructive demolition when the traditional busbar is changed, and reducing the cost of expansion and adjustment.

Modular connection supports multi-path expansion and can meet the diversified expansion needs of the distribution system. System expansion may involve horizontal extension (such as increasing the distribution range on the same floor), vertical extension (such as extending upstairs and downstairs) or branch extension (such as leading multiple sub-circuits from the main busbar). The modules of aluminum electrical compact busbar contain multiple functional units. Linear modules are used for horizontal extension, vertical modules are used for vertical connection, and branch modules are used to lead out sub-circuits. The flexible combination of these modules makes the expansion path unrestricted. Whether it is a simple line extension or a complex multi-node expansion, it can be achieved through the combination of modules to adapt to the expansion needs of different scenarios.

The load adaptation capability of modular connection allows the power distribution system to accurately match the power requirements of new equipment when it is expanded. Different modules can carry different current specifications, ranging from tens of amperes to thousands of amperes. When expanding, the current level required can be calculated according to the power of the new equipment, and the corresponding specification of the module can be selected to access the system. For example, when adding high-power equipment, a high-current module is selected; when adding low-power equipment, a low-current module is selected, without the need to completely transform the original system. This precise adaptation avoids the waste of resources of "big horses pulling small carts", prevents circuit failures caused by load mismatch, and improves the safety of expansion.

In terms of the coordination of later maintenance and expansion, modular connection makes system adjustment more convenient. The expansion of the distribution system often requires maintenance work, such as replacing aging components and detecting line status. The modules of the aluminum electrical compact busbar can be disassembled separately, and the old modules nearby can be replaced at the same time when expanding, without interrupting the power supply of the entire system. For example, when expanding a section of busbar, the power supply of the module can be disconnected first, and the aging connection components can be replaced before connecting the new module. The whole process does not affect the normal power supply of other areas, and the expansion and maintenance can be carried out simultaneously, which improves the overall operation efficiency of the system.

The standardized design of modular connection reserves space for larger-scale expansion in the future. As the demand for electricity continues to grow, the distribution system may need to be expanded multiple times. The module specifications of aluminum electrical compact busbar remain consistent for a long time, and the modules installed in the early stage can be compatible with the modules added later. For example, when a busbar system installed in a factory was expanded on a large scale ten years later, the newly added modules could still be perfectly connected with the original system, without having to replace the entire system due to incompatible specifications. This provides a stable foundation for long-term expansion and protects the initial equipment investment.