How does a hot-dip galvanized cable tray maintain stable performance in high-temperature environments?

Release Time : 2025-10-23

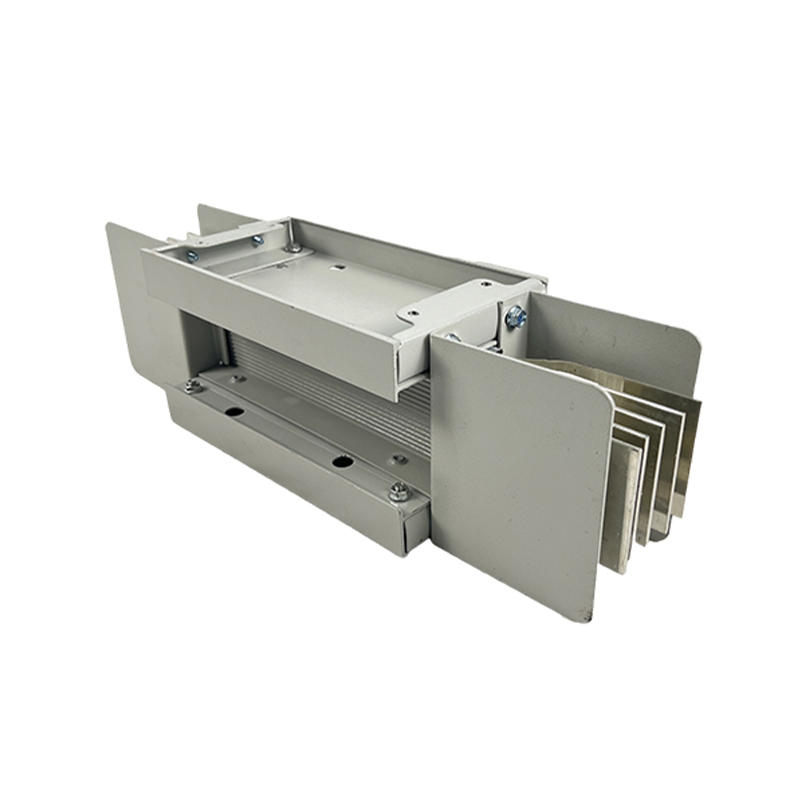

With the rapid development of modern industry and infrastructure, cable trays, as crucial support and protection devices in power systems, are operating in increasingly complex environments. High-temperature industrial environments, such as metallurgy, chemical engineering, and power plants, place particular demands on cable tray materials for heat resistance, corrosion resistance, and structural stability. Among various cable tray materials, hot-dip galvanized cable tray is widely used due to its excellent overall performance.

1. Basic Structure and Protection Principle of Hot-Dip Galvanized Cable Tray

Hot-dip galvanized cable tray uses high-quality carbon steel as its substrate. After pre-treatments such as pickling, fluxing, and drying, it is immersed in molten zinc at approximately 450°C, forming a dense zinc-iron alloy coating on the steel surface. This coating, composed of multiple layers of intermetallic compounds, not only provides excellent adhesion and mechanical strength but also provides electrochemical protection to the steel substrate through a "sacrificial anode" mechanism, effectively preventing corrosion.

2. Mechanisms of High-Temperature Impact on Hot-Dip Galvanized Coatings

In high-temperature environments, the stability of hot-dip galvanized coatings is primarily influenced by two factors: the oxidation rate of the zinc layer and the diffusion behavior of the zinc-iron alloy layer. When the ambient temperature exceeds 60°C for extended periods, the zinc layer's surface reacts more rapidly with oxygen in the air, producing corrosion products such as basic zinc carbonate or zinc oxide. While these products can mitigate further corrosion to a certain extent, the corrosion rate accelerates significantly if the temperature rises continuously above 100°C, particularly in high-humidity or sulfur-containing environments. Notably, at temperatures exceeding 200°C, the zinc layer experiences significant hot brittleness, resulting in a decrease in ductility and adhesion. Furthermore, at temperatures reaching 419.5°C, the zinc layer may begin to soften or even partially melt, resulting in a loss of protective properties. Therefore, hot-dip galvanized cable trays can maintain good performance under conventional high-temperature operating conditions, but caution is advised when using them in extremely high-temperature environments.

3. Technical Measures to Improve High-Temperature Stability

To enhance the durability of hot-dip galvanized cable trays in high-temperature environments, various technical measures can be employed. First, controlling the thickness of the galvanized coating is crucial. It is generally recommended to use products with a coating thickness of at least 65μm in high-temperature areas to extend their service life. Secondly, a "galvanizing + coating" composite protection system, such as applying a high-temperature-resistant organic coating on the galvanized layer, can significantly isolate oxygen and corrosive media, improving overall aging resistance. Furthermore, improving the steel material can enhance the thermal stability of the bridge. Using low-silicon killed steel as the base material can avoid the "Sanderin effect," which causes abnormally thick coatings and increased brittleness due to silicon, thereby ensuring a uniform and secure coating.

4. Design and Maintenance Strategies in Practical Applications

When installing hot-dip galvanized bridges in high-temperature locations, scientific design principles should be followed. For example, the bridge should be routed appropriately to avoid direct heat radiation sources or steam exhaust vents. Thermal insulation barriers or air circulation channels should be installed between the bridge and high-temperature equipment to reduce local temperature rise. Furthermore, regular bridge inspections should be conducted, focusing on corrosion-prone areas such as connectors, welds, and cut edges. Dust and oil deposits should be promptly cleaned to prevent the exacerbation of localized electrochemical corrosion. For special applications where temperatures exceed 150°C for extended periods, alternative options are recommended, such as stainless steel or aluminum alloy cable trays, or cable trays with specially treated, heavy-duty corrosion-resistant coatings, to ensure long-term safe and reliable system operation.

Hot-dip galvanized cable trays offer excellent performance stability in generally high-temperature environments. Their zinc-iron alloy coating effectively resists corrosion and maintains structural integrity. Their heat and corrosion resistance can be further enhanced through optimized coating processes, the use of composite protection technologies, and scientific engineering design. However, for extremely high-temperature conditions, material selection and evaluation must be considered based on specific operating conditions. In the future, with the development of new materials and processes, the application prospects of hot-dip galvanized cable trays in high-temperature environments will expand even further.

1. Basic Structure and Protection Principle of Hot-Dip Galvanized Cable Tray

Hot-dip galvanized cable tray uses high-quality carbon steel as its substrate. After pre-treatments such as pickling, fluxing, and drying, it is immersed in molten zinc at approximately 450°C, forming a dense zinc-iron alloy coating on the steel surface. This coating, composed of multiple layers of intermetallic compounds, not only provides excellent adhesion and mechanical strength but also provides electrochemical protection to the steel substrate through a "sacrificial anode" mechanism, effectively preventing corrosion.

2. Mechanisms of High-Temperature Impact on Hot-Dip Galvanized Coatings

In high-temperature environments, the stability of hot-dip galvanized coatings is primarily influenced by two factors: the oxidation rate of the zinc layer and the diffusion behavior of the zinc-iron alloy layer. When the ambient temperature exceeds 60°C for extended periods, the zinc layer's surface reacts more rapidly with oxygen in the air, producing corrosion products such as basic zinc carbonate or zinc oxide. While these products can mitigate further corrosion to a certain extent, the corrosion rate accelerates significantly if the temperature rises continuously above 100°C, particularly in high-humidity or sulfur-containing environments. Notably, at temperatures exceeding 200°C, the zinc layer experiences significant hot brittleness, resulting in a decrease in ductility and adhesion. Furthermore, at temperatures reaching 419.5°C, the zinc layer may begin to soften or even partially melt, resulting in a loss of protective properties. Therefore, hot-dip galvanized cable trays can maintain good performance under conventional high-temperature operating conditions, but caution is advised when using them in extremely high-temperature environments.

3. Technical Measures to Improve High-Temperature Stability

To enhance the durability of hot-dip galvanized cable trays in high-temperature environments, various technical measures can be employed. First, controlling the thickness of the galvanized coating is crucial. It is generally recommended to use products with a coating thickness of at least 65μm in high-temperature areas to extend their service life. Secondly, a "galvanizing + coating" composite protection system, such as applying a high-temperature-resistant organic coating on the galvanized layer, can significantly isolate oxygen and corrosive media, improving overall aging resistance. Furthermore, improving the steel material can enhance the thermal stability of the bridge. Using low-silicon killed steel as the base material can avoid the "Sanderin effect," which causes abnormally thick coatings and increased brittleness due to silicon, thereby ensuring a uniform and secure coating.

4. Design and Maintenance Strategies in Practical Applications

When installing hot-dip galvanized bridges in high-temperature locations, scientific design principles should be followed. For example, the bridge should be routed appropriately to avoid direct heat radiation sources or steam exhaust vents. Thermal insulation barriers or air circulation channels should be installed between the bridge and high-temperature equipment to reduce local temperature rise. Furthermore, regular bridge inspections should be conducted, focusing on corrosion-prone areas such as connectors, welds, and cut edges. Dust and oil deposits should be promptly cleaned to prevent the exacerbation of localized electrochemical corrosion. For special applications where temperatures exceed 150°C for extended periods, alternative options are recommended, such as stainless steel or aluminum alloy cable trays, or cable trays with specially treated, heavy-duty corrosion-resistant coatings, to ensure long-term safe and reliable system operation.

Hot-dip galvanized cable trays offer excellent performance stability in generally high-temperature environments. Their zinc-iron alloy coating effectively resists corrosion and maintains structural integrity. Their heat and corrosion resistance can be further enhanced through optimized coating processes, the use of composite protection technologies, and scientific engineering design. However, for extremely high-temperature conditions, material selection and evaluation must be considered based on specific operating conditions. In the future, with the development of new materials and processes, the application prospects of hot-dip galvanized cable trays in high-temperature environments will expand even further.