How does a trunking cable tray achieve orderly cable routing?

Release Time : 2025-11-10

In modern buildings, data centers, industrial plants, and smart buildings, hundreds or even thousands of power lines, control lines, communication lines, and fiber optic cables act like the "nerves" of a city, supporting equipment operation, information transmission, and energy supply. However, without scientific planning and proper guidance, these cables easily become tangled and chaotic, affecting not only aesthetics but also causing poor heat dissipation, maintenance difficulties, and even safety hazards. In this context, a trunking cable tray acts as a "magic channel" for efficient cabling, using its structured and modular design to allow for orderly routing, safe passage, and intelligent management of complex cables.

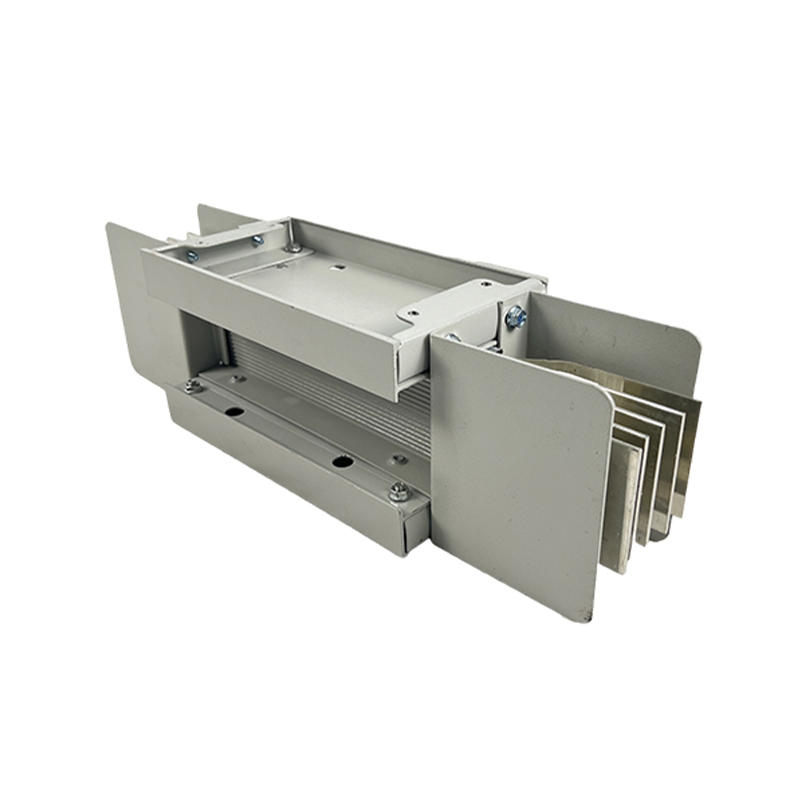

1. Structural Design: From "Disorderly" to "Orderly"

While trunking cable trays vary in shape, their core objective remains the same: to provide physical support and path guidance for cables. Through standardized cross-sectional dimensions, layered layouts, and partition designs, the cable tray system can lay high-voltage, low-voltage, and signal lines according to functional zones, effectively avoiding electromagnetic interference. For example, in data center server rooms, the upper layer of cable trays carries fiber optic and network cables, while the lower layer carries power cables, with metal partitions in between. This meets regulatory requirements and facilitates future expansion. Furthermore, the cable tray system supports flexible horizontal and vertical maneuvers, and with the addition of elbows, tees, and crosses, it can easily bypass beams, columns, pipes, or equipment obstacles, achieving "three-dimensional cabling." This modular assembly method significantly improves construction efficiency and ensures clear cable routing and labeling, eliminating the "spider web" of messy cabling.

2. Materials and Processes: Balancing Strength, Fire Resistance, and Durability

Efficient cabling requires not only neatness but also reliability. High-quality cable trays are often made of galvanized steel, aluminum alloy, or flame-retardant engineering plastics. The galvanized layer provides excellent corrosion resistance, suitable for humid or corrosive industrial environments; aluminum alloy is lightweight and high-strength, suitable for high-rise buildings with stringent load-bearing requirements; and flame-retardant PVC cable trays are widely used in office spaces, offering insulation, quiet operation, and cost advantages. Meanwhile, modern cable tray products generally pass national fire protection, environmental protection, and electrical safety certifications. Some high-end cable trays also integrate grounding terminals to ensure reliable grounding of the metal structure, preventing static electricity buildup or leakage risks, and further enhancing system safety.

3. Intelligent Management: Making Cables "Visible and Manageable"

With the increasing demand for intelligent operation and maintenance, cable tray systems are evolving towards "visualization and manageability." For example, pre-embedded RFID tags or QR code markings inside the cable tray, combined with mobile terminal scanning, allow for quick location of the start, end, and purpose of a cable; some data centers even use cable trays with transparent covers, enabling a clear view of the internal cable status. Furthermore, the cable tray design fully considers heat dissipation and maintenance space. Open ladder-style cable trays facilitate air circulation, reducing cable temperature rise; while removable covers or quick-release clip structures allow for the addition or removal of cables without complete disassembly, greatly shortening troubleshooting and modification time.

4. Green Construction: Cost Reduction and Efficiency Improvement, Contributing to Sustainable Development

Compared to traditional conduit cabling, cable tray systems shorten the construction cycle by more than 30%, and the materials have a high recyclability rate. Its standardized design reduces on-site cutting and welding, lowers dust and noise pollution, and aligns with green building principles. Simultaneously, orderly cabling reduces cable crossing friction and bending damage, extending service life and indirectly lowering overall lifecycle maintenance costs.

The trunking cable tray, seemingly ordinary, is an indispensable "skeleton" of modern electrical and intelligent systems. With its scientific structure, reliable materials, and forward-thinking management, it transforms messy cables into a clear, safe, and efficient transmission network. It is thanks to this "magic channel" that our buildings can truly achieve "internal harmony and external order"—invisible cables enabling visible intelligence and safety.

1. Structural Design: From "Disorderly" to "Orderly"

While trunking cable trays vary in shape, their core objective remains the same: to provide physical support and path guidance for cables. Through standardized cross-sectional dimensions, layered layouts, and partition designs, the cable tray system can lay high-voltage, low-voltage, and signal lines according to functional zones, effectively avoiding electromagnetic interference. For example, in data center server rooms, the upper layer of cable trays carries fiber optic and network cables, while the lower layer carries power cables, with metal partitions in between. This meets regulatory requirements and facilitates future expansion. Furthermore, the cable tray system supports flexible horizontal and vertical maneuvers, and with the addition of elbows, tees, and crosses, it can easily bypass beams, columns, pipes, or equipment obstacles, achieving "three-dimensional cabling." This modular assembly method significantly improves construction efficiency and ensures clear cable routing and labeling, eliminating the "spider web" of messy cabling.

2. Materials and Processes: Balancing Strength, Fire Resistance, and Durability

Efficient cabling requires not only neatness but also reliability. High-quality cable trays are often made of galvanized steel, aluminum alloy, or flame-retardant engineering plastics. The galvanized layer provides excellent corrosion resistance, suitable for humid or corrosive industrial environments; aluminum alloy is lightweight and high-strength, suitable for high-rise buildings with stringent load-bearing requirements; and flame-retardant PVC cable trays are widely used in office spaces, offering insulation, quiet operation, and cost advantages. Meanwhile, modern cable tray products generally pass national fire protection, environmental protection, and electrical safety certifications. Some high-end cable trays also integrate grounding terminals to ensure reliable grounding of the metal structure, preventing static electricity buildup or leakage risks, and further enhancing system safety.

3. Intelligent Management: Making Cables "Visible and Manageable"

With the increasing demand for intelligent operation and maintenance, cable tray systems are evolving towards "visualization and manageability." For example, pre-embedded RFID tags or QR code markings inside the cable tray, combined with mobile terminal scanning, allow for quick location of the start, end, and purpose of a cable; some data centers even use cable trays with transparent covers, enabling a clear view of the internal cable status. Furthermore, the cable tray design fully considers heat dissipation and maintenance space. Open ladder-style cable trays facilitate air circulation, reducing cable temperature rise; while removable covers or quick-release clip structures allow for the addition or removal of cables without complete disassembly, greatly shortening troubleshooting and modification time.

4. Green Construction: Cost Reduction and Efficiency Improvement, Contributing to Sustainable Development

Compared to traditional conduit cabling, cable tray systems shorten the construction cycle by more than 30%, and the materials have a high recyclability rate. Its standardized design reduces on-site cutting and welding, lowers dust and noise pollution, and aligns with green building principles. Simultaneously, orderly cabling reduces cable crossing friction and bending damage, extending service life and indirectly lowering overall lifecycle maintenance costs.

The trunking cable tray, seemingly ordinary, is an indispensable "skeleton" of modern electrical and intelligent systems. With its scientific structure, reliable materials, and forward-thinking management, it transforms messy cables into a clear, safe, and efficient transmission network. It is thanks to this "magic channel" that our buildings can truly achieve "internal harmony and external order"—invisible cables enabling visible intelligence and safety.