How Does an Aluminum Electrical Compact Busbar Bear the Heavy Responsibility of Power Conduction?

Release Time : 2025-11-24

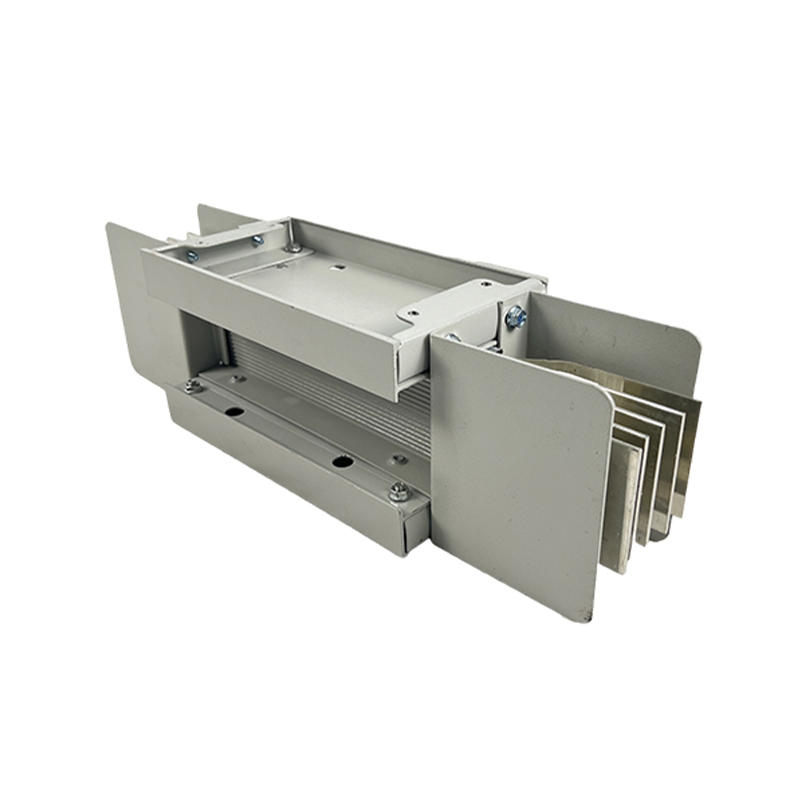

In modern power systems, industrial power distribution, and new energy equipment, electrical busbars serve as the "main artery" of power transmission, and their performance directly affects the safety, efficiency, and spatial layout of the entire system. In recent years, aluminum electrical compact busbars, with their unique material advantages and structural innovations, have gradually become an important alternative to traditional copper busbars. They not only significantly reduce system weight but also achieve efficient and reliable power transmission within limited space, truly "bearing the heavy responsibility of power conduction with a lightweight body."

1. Lightweight Design, Unlocking Installation and Transportation Advantages

Aluminum naturally possesses low density, making the overall weight of aluminum busbars significantly lower than that of copper busbars with equivalent conductivity. This advantage is particularly prominent in large-scale engineering projects—whether it's the vertical distribution shafts of high-rise buildings, the onboard electrical cabinets of rail transit, or the internal wiring of wind power converters and photovoltaic inverters, lightweight busbars can effectively reduce structural load-bearing requirements, simplify hoisting and handling processes, and reduce labor and machinery costs. Meanwhile, aluminum busbars are indispensable key components in mobile or weight-sensitive applications.

2. Compact Structure Optimizes Space Utilization

"Compact" is not just a description of the shape, but a system-level design concept. Aluminum busbars, through precision extrusion molding, irregular cross-section design, and multi-layer lamination processes, significantly reduce space occupation while ensuring current carrying capacity. For example, using rectangular, T-shaped, or integrated cross-sections with heat dissipation fins enhances heat dissipation efficiency and facilitates dense arrangement; some products also integrate insulating sheaths or modular connection terminals for plug-and-play functionality, further saving space within the distribution cabinet. This highly integrated design is particularly in line with the current trend of miniaturization and high density in electrical equipment.

3. Excellent Conductivity and Heat Dissipation Ensure Reliable Operation

Although aluminum's conductivity is about 60% that of copper, by reasonably increasing the cross-sectional area and optimizing the current distribution path, aluminum busbars can fully meet the power transmission needs of conventional to medium-to-high power levels. More importantly, aluminum possesses excellent thermal conductivity. Combined with natural convection or forced air cooling in a compact structure, it can quickly dissipate Joule heat, effectively controlling temperature rise and preventing increased contact resistance or insulation aging due to overheating. In long-term full-load operation tests, high-quality aluminum busbar systems exhibit stable temperature rise curves and low-loss characteristics, fully validating their engineering applicability.

4. Surface Treatment Technology Enhances Connection Reliability

In the past, the ease of oxidation and unstable contact resistance of aluminum limited its application in high-end electrical connections. Now, through advanced surface treatment processes—such as tin plating, silver plating, micro-arc oxidation, or specialized anti-oxidation coatings—the contact surface stability of aluminum busbars has been fundamentally improved. These treatments not only isolate air to prevent oxide film regeneration but also significantly reduce contact resistance, ensuring that bolted connections or plug-in interfaces maintain low resistance and high conductivity under vibration, temperature changes, and other conditions, fundamentally solving the "historical pain points" of aluminum connections.

5. Win-Win for Economy and Sustainability

From a life-cycle cost perspective, the abundant reserves and relatively stable price of aluminum resources give aluminum busbars a significant advantage in initial procurement costs. Simultaneously, the savings in transportation and installation due to their lightweight design, along with their excellent recyclability, further enhance their dual economic and environmental value. Against the backdrop of global advocacy for green manufacturing and low-carbon transformation, aluminum compact busbars are becoming an ideal choice for building efficient and sustainable power infrastructure.

The aluminum electrical compact busbar is not simply a "replacement of copper with aluminum," but rather the result of a deep integration of materials science, structural engineering, and electrical technology. It achieves systematic breakthroughs in lightweighting, space efficiency, thermal management, and connection reliability, successfully combining "lightweight" and "powerful."

1. Lightweight Design, Unlocking Installation and Transportation Advantages

Aluminum naturally possesses low density, making the overall weight of aluminum busbars significantly lower than that of copper busbars with equivalent conductivity. This advantage is particularly prominent in large-scale engineering projects—whether it's the vertical distribution shafts of high-rise buildings, the onboard electrical cabinets of rail transit, or the internal wiring of wind power converters and photovoltaic inverters, lightweight busbars can effectively reduce structural load-bearing requirements, simplify hoisting and handling processes, and reduce labor and machinery costs. Meanwhile, aluminum busbars are indispensable key components in mobile or weight-sensitive applications.

2. Compact Structure Optimizes Space Utilization

"Compact" is not just a description of the shape, but a system-level design concept. Aluminum busbars, through precision extrusion molding, irregular cross-section design, and multi-layer lamination processes, significantly reduce space occupation while ensuring current carrying capacity. For example, using rectangular, T-shaped, or integrated cross-sections with heat dissipation fins enhances heat dissipation efficiency and facilitates dense arrangement; some products also integrate insulating sheaths or modular connection terminals for plug-and-play functionality, further saving space within the distribution cabinet. This highly integrated design is particularly in line with the current trend of miniaturization and high density in electrical equipment.

3. Excellent Conductivity and Heat Dissipation Ensure Reliable Operation

Although aluminum's conductivity is about 60% that of copper, by reasonably increasing the cross-sectional area and optimizing the current distribution path, aluminum busbars can fully meet the power transmission needs of conventional to medium-to-high power levels. More importantly, aluminum possesses excellent thermal conductivity. Combined with natural convection or forced air cooling in a compact structure, it can quickly dissipate Joule heat, effectively controlling temperature rise and preventing increased contact resistance or insulation aging due to overheating. In long-term full-load operation tests, high-quality aluminum busbar systems exhibit stable temperature rise curves and low-loss characteristics, fully validating their engineering applicability.

4. Surface Treatment Technology Enhances Connection Reliability

In the past, the ease of oxidation and unstable contact resistance of aluminum limited its application in high-end electrical connections. Now, through advanced surface treatment processes—such as tin plating, silver plating, micro-arc oxidation, or specialized anti-oxidation coatings—the contact surface stability of aluminum busbars has been fundamentally improved. These treatments not only isolate air to prevent oxide film regeneration but also significantly reduce contact resistance, ensuring that bolted connections or plug-in interfaces maintain low resistance and high conductivity under vibration, temperature changes, and other conditions, fundamentally solving the "historical pain points" of aluminum connections.

5. Win-Win for Economy and Sustainability

From a life-cycle cost perspective, the abundant reserves and relatively stable price of aluminum resources give aluminum busbars a significant advantage in initial procurement costs. Simultaneously, the savings in transportation and installation due to their lightweight design, along with their excellent recyclability, further enhance their dual economic and environmental value. Against the backdrop of global advocacy for green manufacturing and low-carbon transformation, aluminum compact busbars are becoming an ideal choice for building efficient and sustainable power infrastructure.

The aluminum electrical compact busbar is not simply a "replacement of copper with aluminum," but rather the result of a deep integration of materials science, structural engineering, and electrical technology. It achieves systematic breakthroughs in lightweighting, space efficiency, thermal management, and connection reliability, successfully combining "lightweight" and "powerful."