How to choose an efficient aluminum electrical compact busbar for high-load industrial applications?

Release Time : 2025-04-28

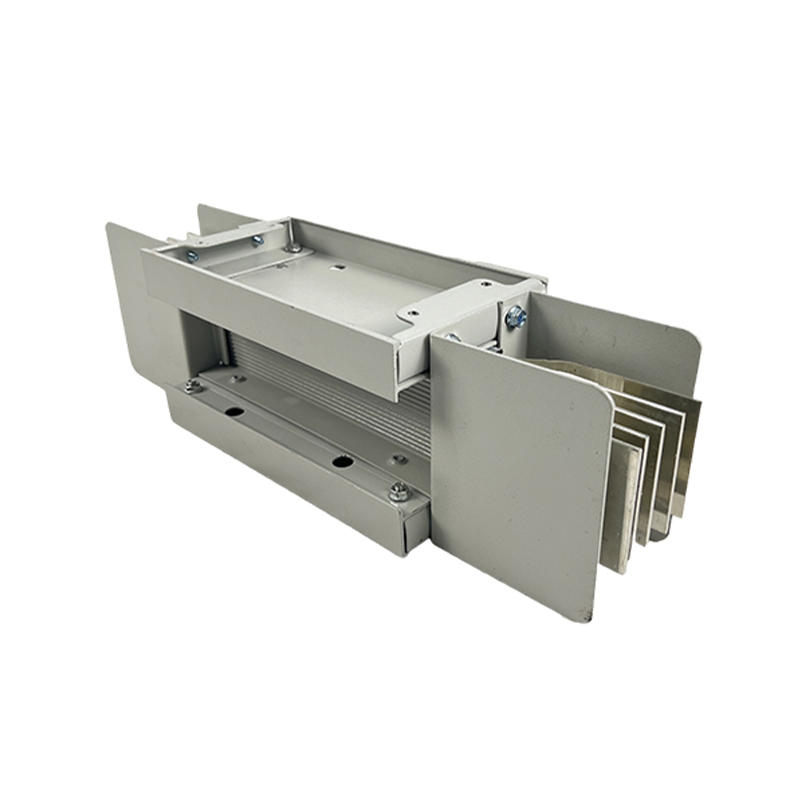

When choosing an efficient aluminum electrical compact busbar for high-load industrial applications, multiple factors need to be considered to ensure the safety, reliability and economy of the system. Aluminum electrical compact busbars are widely used in many industrial fields due to their light weight, good conductivity and compact design. However, it is not easy to select the right aluminum electrical compact busbar for a specific application scenario, and it needs to be considered from multiple angles such as material selection, structural design, installation convenience and long-term maintenance.

First of all, the choice of materials is the basis for determining the performance of aluminum electrical compact busbars. Although aluminum itself has high conductivity and light weight, pure aluminum has shortcomings in strength and durability. Therefore, aluminum alloys are usually used to manufacture busbars. This alloy not only inherits the advantages of aluminum, but also enhances mechanical strength and corrosion resistance by adding other elements. For high-load industrial applications, it is particularly important to select aluminum alloys with high strength and good conductivity, which can withstand large mechanical stress without deformation or damage while ensuring current transmission efficiency.

Secondly, the compact design helps save space and improve system integration. In many industrial environments, space efficiency is crucial. Compact aluminum electrical busbars achieve higher current density and smaller footprint by optimizing cross-sectional shapes and sizes. For example, some designs use rectangular or trapezoidal cross-sections, which can better fit into small spaces and provide a larger surface area to enhance heat dissipation than traditional round cables. In addition, the compact design can also reduce resistance losses on the power transmission path, further improving energy efficiency.

Furthermore, considering that industrial environments are often harsh, aluminum electrical compact busbars with good protective properties are particularly necessary. These protective properties include but are not limited to waterproof, dustproof, corrosion-resistant and fireproof. Especially in places such as chemical plants, steel mills or coastal areas that are sensitive to metal corrosion, choosing busbars with special surface treatment can effectively extend the service life. For example, anodizing or spraying anti-corrosion coatings can significantly improve the weather resistance of the busbar without sacrificing conductive properties.

Ease of installation is also an important criterion for evaluating aluminum electrical compact busbars. The ideal busbar should be easy to carry, cut and assemble, which not only speeds up the construction schedule but also reduces labor costs. To this end, manufacturers have developed a variety of connection methods, such as plug-in and bolt-on, to facilitate quick installation on site. At the same time, in order to simplify the subsequent maintenance work, some busbar products are also equipped with visual status indicators or intelligent monitoring systems, so that operators can understand the working status of the busbar in real time and find potential fault points in time.

In addition, considering the electromagnetic compatibility issues in high-load industrial applications, the selection of aluminum electrical compact busbars with good shielding effect cannot be ignored. Efficient shielding measures can effectively suppress electromagnetic interference and protect sensitive equipment from external electromagnetic fields. This usually involves the design of the busbar housing and the selection of internal insulation materials to ensure that the entire system operates stably in a complex electromagnetic environment.

Finally, before making a final decision, the cost-effectiveness of the aluminum electrical compact busbar needs to be fully evaluated. Although the initial investment may be higher than that of traditional cables, in the long run, the overall cost of ownership is actually lower due to its lower operating loss, longer service life and less maintenance requirements. In addition, with technological advances and large-scale production, the price of aluminum electrical compact busbars is also gradually decreasing, making it a preferred option for more and more industrial projects.

In summary, the selection of efficient aluminum electrical compact busbars suitable for high-load industrial applications requires a comprehensive analysis of multiple dimensions, including material quality, structural design, protection characteristics, installation convenience, electromagnetic compatibility, and economic benefits. Only in this way can we ensure that the selected products can meet current needs and adapt to future developments and changes, providing long-lasting and reliable power support for industrial projects.

First of all, the choice of materials is the basis for determining the performance of aluminum electrical compact busbars. Although aluminum itself has high conductivity and light weight, pure aluminum has shortcomings in strength and durability. Therefore, aluminum alloys are usually used to manufacture busbars. This alloy not only inherits the advantages of aluminum, but also enhances mechanical strength and corrosion resistance by adding other elements. For high-load industrial applications, it is particularly important to select aluminum alloys with high strength and good conductivity, which can withstand large mechanical stress without deformation or damage while ensuring current transmission efficiency.

Secondly, the compact design helps save space and improve system integration. In many industrial environments, space efficiency is crucial. Compact aluminum electrical busbars achieve higher current density and smaller footprint by optimizing cross-sectional shapes and sizes. For example, some designs use rectangular or trapezoidal cross-sections, which can better fit into small spaces and provide a larger surface area to enhance heat dissipation than traditional round cables. In addition, the compact design can also reduce resistance losses on the power transmission path, further improving energy efficiency.

Furthermore, considering that industrial environments are often harsh, aluminum electrical compact busbars with good protective properties are particularly necessary. These protective properties include but are not limited to waterproof, dustproof, corrosion-resistant and fireproof. Especially in places such as chemical plants, steel mills or coastal areas that are sensitive to metal corrosion, choosing busbars with special surface treatment can effectively extend the service life. For example, anodizing or spraying anti-corrosion coatings can significantly improve the weather resistance of the busbar without sacrificing conductive properties.

Ease of installation is also an important criterion for evaluating aluminum electrical compact busbars. The ideal busbar should be easy to carry, cut and assemble, which not only speeds up the construction schedule but also reduces labor costs. To this end, manufacturers have developed a variety of connection methods, such as plug-in and bolt-on, to facilitate quick installation on site. At the same time, in order to simplify the subsequent maintenance work, some busbar products are also equipped with visual status indicators or intelligent monitoring systems, so that operators can understand the working status of the busbar in real time and find potential fault points in time.

In addition, considering the electromagnetic compatibility issues in high-load industrial applications, the selection of aluminum electrical compact busbars with good shielding effect cannot be ignored. Efficient shielding measures can effectively suppress electromagnetic interference and protect sensitive equipment from external electromagnetic fields. This usually involves the design of the busbar housing and the selection of internal insulation materials to ensure that the entire system operates stably in a complex electromagnetic environment.

Finally, before making a final decision, the cost-effectiveness of the aluminum electrical compact busbar needs to be fully evaluated. Although the initial investment may be higher than that of traditional cables, in the long run, the overall cost of ownership is actually lower due to its lower operating loss, longer service life and less maintenance requirements. In addition, with technological advances and large-scale production, the price of aluminum electrical compact busbars is also gradually decreasing, making it a preferred option for more and more industrial projects.

In summary, the selection of efficient aluminum electrical compact busbars suitable for high-load industrial applications requires a comprehensive analysis of multiple dimensions, including material quality, structural design, protection characteristics, installation convenience, electromagnetic compatibility, and economic benefits. Only in this way can we ensure that the selected products can meet current needs and adapt to future developments and changes, providing long-lasting and reliable power support for industrial projects.