Hot dip galvanized cable tray helps upgrade modern energy systems

Release Time : 2025-05-12

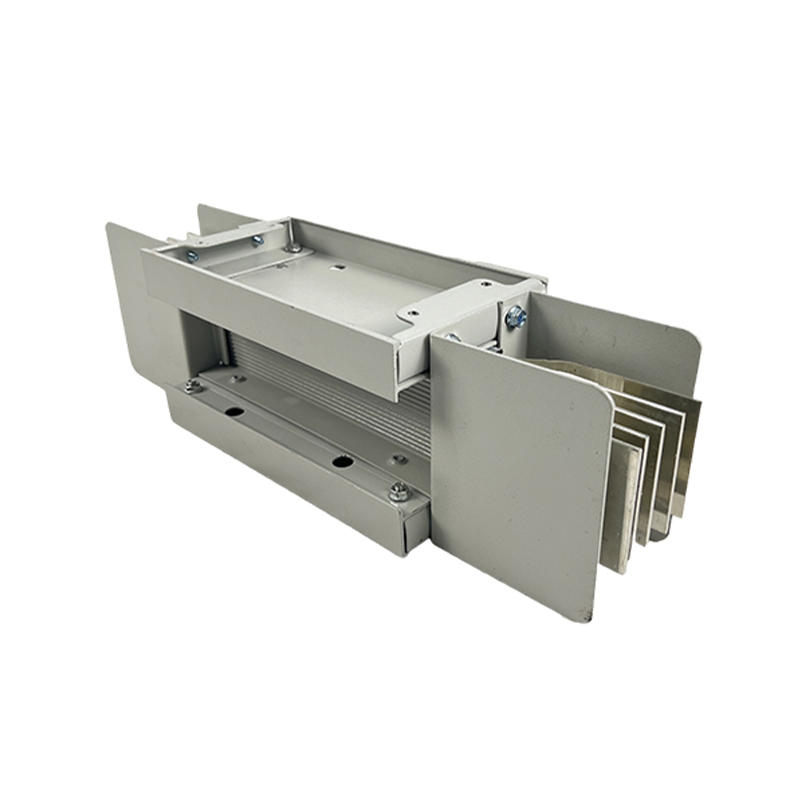

With the growing global demand for clean energy and the rapid development of smart grid technology, the reliability and efficiency of power transmission and distribution systems have become particularly important. As a high-performance infrastructure component, hot dip galvanized cable tray plays a vital role in modern energy systems. It not only provides physical protection for cables, but also greatly improves the safety and durability of the entire power network through its excellent corrosion resistance and stability.

Strong and durable, ensuring long-term stable operation

Hot dip galvanized cable tray uses high-quality steel and is treated by hot dip galvanizing process to form a uniform and dense zinc layer. This zinc coating not only effectively prevents the substrate from contacting the external environment, avoiding oxidation and corrosion, but also has good mechanical strength and can withstand large loads without deformation. This feature is particularly critical in complex outdoor environments such as coastal areas, chemical plants or heavily polluted urban areas, because it ensures that the cable tray can maintain stable performance for a long time even under harsh conditions, reducing maintenance costs and frequency.

Improve electrical system safety

In addition to physical protection, hot dip galvanized cable tray can significantly improve the safety of electrical systems. On the one hand, the galvanized layer has certain fireproof properties, which can slow down the spread of flames to a certain extent and buy precious time for emergency response; on the other hand, due to its smooth surface, it is not easy to accumulate dust or other debris, reducing the risk of fire caused by short circuit. In addition, good grounding design is also one of the important factors to ensure personnel safety, and hot dip galvanized cable tray also performs well in this regard, providing a reliable conductive path.

Supporting the construction of intelligent power distribution networks

With the application of Internet of Things (IoT) technology and big data analysis tools, smart grids are becoming a reality. With its standardized design and modular structure, hot dip galvanized cable tray is very suitable for integrating various sensors and communication devices to achieve real-time monitoring of power grid status. For example, installing temperature sensors can monitor the operating temperature of cables to prevent overheating; while vibration sensors can be used to detect illegal intrusions and enhance network security protection. These intelligent functions enable power operators to manage assets more accurately, optimize resource allocation, and respond to potential failures in a timely manner, improving overall operational efficiency and service quality.

Promoting green and sustainable development

In the context of global advocacy of low-carbon economy, choosing environmentally friendly building materials is crucial to promoting green development. The galvanizing process used in hot dip galvanized cable tray meets strict environmental standards, generates less waste during the production process, and most of the materials can be recycled. In addition, due to its long service life, it reduces the resources required for frequent replacement, further reducing the carbon footprint. Therefore, the use of hot dip galvanized cable tray is not only a manifestation of corporate social responsibility, but also a positive contribution to the construction of sustainable smart cities.

In summary, hot dip galvanized cable tray is gradually becoming an indispensable part of the upgrade of modern energy systems with its excellent durability, safety and adaptability. Whether it is a new project or the renovation of old facilities, choosing the right cable tray is a key step to ensure the efficient operation of the power grid.

Strong and durable, ensuring long-term stable operation

Hot dip galvanized cable tray uses high-quality steel and is treated by hot dip galvanizing process to form a uniform and dense zinc layer. This zinc coating not only effectively prevents the substrate from contacting the external environment, avoiding oxidation and corrosion, but also has good mechanical strength and can withstand large loads without deformation. This feature is particularly critical in complex outdoor environments such as coastal areas, chemical plants or heavily polluted urban areas, because it ensures that the cable tray can maintain stable performance for a long time even under harsh conditions, reducing maintenance costs and frequency.

Improve electrical system safety

In addition to physical protection, hot dip galvanized cable tray can significantly improve the safety of electrical systems. On the one hand, the galvanized layer has certain fireproof properties, which can slow down the spread of flames to a certain extent and buy precious time for emergency response; on the other hand, due to its smooth surface, it is not easy to accumulate dust or other debris, reducing the risk of fire caused by short circuit. In addition, good grounding design is also one of the important factors to ensure personnel safety, and hot dip galvanized cable tray also performs well in this regard, providing a reliable conductive path.

Supporting the construction of intelligent power distribution networks

With the application of Internet of Things (IoT) technology and big data analysis tools, smart grids are becoming a reality. With its standardized design and modular structure, hot dip galvanized cable tray is very suitable for integrating various sensors and communication devices to achieve real-time monitoring of power grid status. For example, installing temperature sensors can monitor the operating temperature of cables to prevent overheating; while vibration sensors can be used to detect illegal intrusions and enhance network security protection. These intelligent functions enable power operators to manage assets more accurately, optimize resource allocation, and respond to potential failures in a timely manner, improving overall operational efficiency and service quality.

Promoting green and sustainable development

In the context of global advocacy of low-carbon economy, choosing environmentally friendly building materials is crucial to promoting green development. The galvanizing process used in hot dip galvanized cable tray meets strict environmental standards, generates less waste during the production process, and most of the materials can be recycled. In addition, due to its long service life, it reduces the resources required for frequent replacement, further reducing the carbon footprint. Therefore, the use of hot dip galvanized cable tray is not only a manifestation of corporate social responsibility, but also a positive contribution to the construction of sustainable smart cities.

In summary, hot dip galvanized cable tray is gradually becoming an indispensable part of the upgrade of modern energy systems with its excellent durability, safety and adaptability. Whether it is a new project or the renovation of old facilities, choosing the right cable tray is a key step to ensure the efficient operation of the power grid.