How does a cable tray made of galvanized steel enhance its corrosion resistance?

Release Time : 2025-06-09

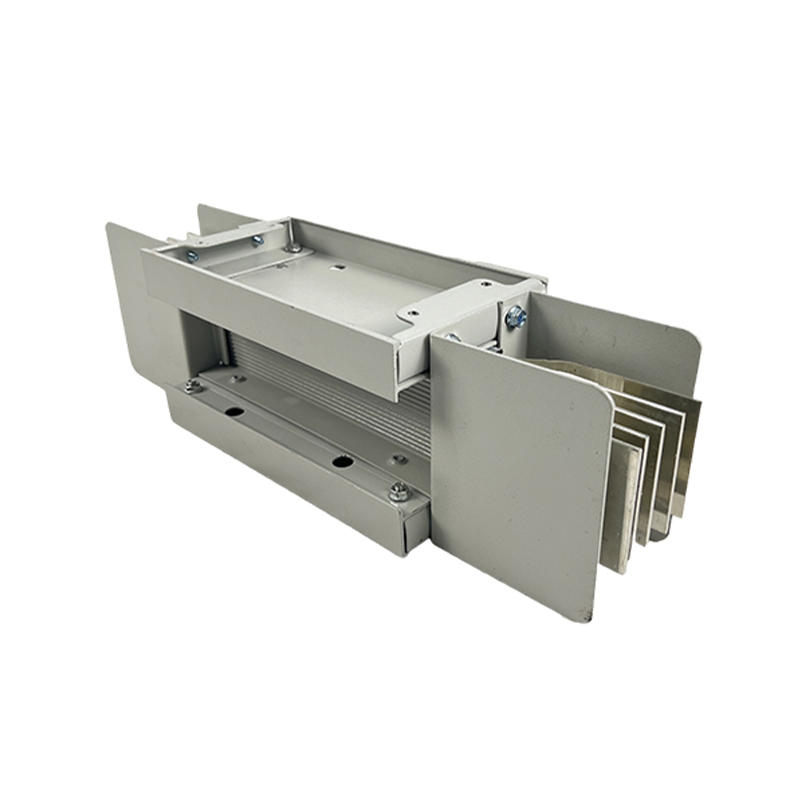

Cable trays made of galvanized steel have shown significant advantages in improving corrosion resistance. The galvanizing process not only enhances the durability of the material itself, but also effectively extends the service life of the cable tray by forming a zinc layer on the surface of the steel. The application of this technology enables the cable tray to operate stably and for a long time in various harsh environments, providing a solid guarantee for power transmission and communication systems.

First, the galvanizing process gives steel excellent rust resistance. When the surface of the steel is hot-dip galvanized or electro-galvanized, a tight zinc layer will be formed on its surface. This zinc layer can effectively isolate oxygen and moisture in the air, preventing the steel from direct contact with the external environment, thereby avoiding the occurrence of oxidation reactions. Even in humid or rainy environments, galvanized steel cable trays can remain in good condition and are not easy to rust or corrode. This feature is especially important for outdoor applications, as these places are usually faced with more severe climatic conditions.

Secondly, galvanized steel cable trays have excellent self-healing capabilities. Once the surface is slightly scratched or damaged, the exposed steel will react chemically with the surrounding zinc layer to form a new protective film covering the damaged area. This self-healing mechanism ensures that the overall protective performance of the cable tray will not be significantly affected even if a small area of damage occurs during use. In contrast, once the surface of untreated ordinary steel is damaged, it is easy to quickly begin to corrode, and the corrosion range will continue to expand. Therefore, galvanized steel cable tray has obvious advantages in terms of maintenance costs and long-term reliability.

In addition, the presence of the zinc coating improves the cable tray's resistance to mechanical damage. The zinc layer formed during the galvanizing process not only plays an anti-corrosion role, but also enhances the surface hardness of the steel, making it more wear-resistant. This means that during installation, transportation and daily use, the cable tray can better resist external forces such as collisions and friction, reducing the risk of failure caused by physical damage. Especially in places where construction conditions are complex or equipment needs to be moved frequently, galvanized steel cable trays perform well and can ensure the continuous and stable operation of the system.

It is worth noting that galvanized steel cable trays also have excellent weather resistance. Whether facing strong ultraviolet radiation or acid rain erosion, the galvanized layer can provide an effective barrier to prevent harmful substances from invading the internal steel. Especially in areas with severe industrial pollution or coastal areas, the air contains a lot of corrosive gases and salts, and ordinary steel is very easy to rust in such an environment. Galvanized steel cable trays can serve for a long time in these highly corrosive environments with their excellent weather resistance, without frequent replacement or maintenance, greatly reducing operation and maintenance costs.

From the perspective of environmental protection, galvanized steel cable trays also show positive significance. Due to their excellent corrosion resistance, they reduce the generation of waste caused by corrosion, which helps to reduce resource waste and environmental pollution. At the same time, the galvanizing process itself is also developing in a more environmentally friendly direction. The application of new chromium-free passivation technology further reduces the emission of harmful substances in the production process, which meets the requirements of modern society for green manufacturing.

Finally, the design flexibility of galvanized steel cable trays also brings many conveniences to users. Galvanized steel plates of different thicknesses and specifications can be customized and processed into cable trays of various sizes according to actual needs to meet the needs of diverse application scenarios. Moreover, the galvanized layer is evenly attached to the surface of the steel, which will not affect the subsequent processing procedures, such as cutting, drilling and other operations are still carried out smoothly, ensuring the quality consistency of the product in the final forming stage.

In summary, the cable tray made of galvanized steel has significantly enhanced its corrosion resistance through many improvements. It not only effectively solves the problem that traditional steel is easily affected by environmental factors, but also has outstanding performance in durability, self-healing ability and weather resistance. These advantages make galvanized steel cable tray an indispensable and important part of modern engineering construction, providing strong support for the safe operation of various electrical facilities. With the advancement of technology and changes in market demand, galvanized steel cable tray will continue to play an important role in the future and promote the development of related industries to a higher level.

First, the galvanizing process gives steel excellent rust resistance. When the surface of the steel is hot-dip galvanized or electro-galvanized, a tight zinc layer will be formed on its surface. This zinc layer can effectively isolate oxygen and moisture in the air, preventing the steel from direct contact with the external environment, thereby avoiding the occurrence of oxidation reactions. Even in humid or rainy environments, galvanized steel cable trays can remain in good condition and are not easy to rust or corrode. This feature is especially important for outdoor applications, as these places are usually faced with more severe climatic conditions.

Secondly, galvanized steel cable trays have excellent self-healing capabilities. Once the surface is slightly scratched or damaged, the exposed steel will react chemically with the surrounding zinc layer to form a new protective film covering the damaged area. This self-healing mechanism ensures that the overall protective performance of the cable tray will not be significantly affected even if a small area of damage occurs during use. In contrast, once the surface of untreated ordinary steel is damaged, it is easy to quickly begin to corrode, and the corrosion range will continue to expand. Therefore, galvanized steel cable tray has obvious advantages in terms of maintenance costs and long-term reliability.

In addition, the presence of the zinc coating improves the cable tray's resistance to mechanical damage. The zinc layer formed during the galvanizing process not only plays an anti-corrosion role, but also enhances the surface hardness of the steel, making it more wear-resistant. This means that during installation, transportation and daily use, the cable tray can better resist external forces such as collisions and friction, reducing the risk of failure caused by physical damage. Especially in places where construction conditions are complex or equipment needs to be moved frequently, galvanized steel cable trays perform well and can ensure the continuous and stable operation of the system.

It is worth noting that galvanized steel cable trays also have excellent weather resistance. Whether facing strong ultraviolet radiation or acid rain erosion, the galvanized layer can provide an effective barrier to prevent harmful substances from invading the internal steel. Especially in areas with severe industrial pollution or coastal areas, the air contains a lot of corrosive gases and salts, and ordinary steel is very easy to rust in such an environment. Galvanized steel cable trays can serve for a long time in these highly corrosive environments with their excellent weather resistance, without frequent replacement or maintenance, greatly reducing operation and maintenance costs.

From the perspective of environmental protection, galvanized steel cable trays also show positive significance. Due to their excellent corrosion resistance, they reduce the generation of waste caused by corrosion, which helps to reduce resource waste and environmental pollution. At the same time, the galvanizing process itself is also developing in a more environmentally friendly direction. The application of new chromium-free passivation technology further reduces the emission of harmful substances in the production process, which meets the requirements of modern society for green manufacturing.

Finally, the design flexibility of galvanized steel cable trays also brings many conveniences to users. Galvanized steel plates of different thicknesses and specifications can be customized and processed into cable trays of various sizes according to actual needs to meet the needs of diverse application scenarios. Moreover, the galvanized layer is evenly attached to the surface of the steel, which will not affect the subsequent processing procedures, such as cutting, drilling and other operations are still carried out smoothly, ensuring the quality consistency of the product in the final forming stage.

In summary, the cable tray made of galvanized steel has significantly enhanced its corrosion resistance through many improvements. It not only effectively solves the problem that traditional steel is easily affected by environmental factors, but also has outstanding performance in durability, self-healing ability and weather resistance. These advantages make galvanized steel cable tray an indispensable and important part of modern engineering construction, providing strong support for the safe operation of various electrical facilities. With the advancement of technology and changes in market demand, galvanized steel cable tray will continue to play an important role in the future and promote the development of related industries to a higher level.