How to improve the efficiency of the power distribution system by using aluminum electrical compact busbar?

Release Time : 2025-05-26

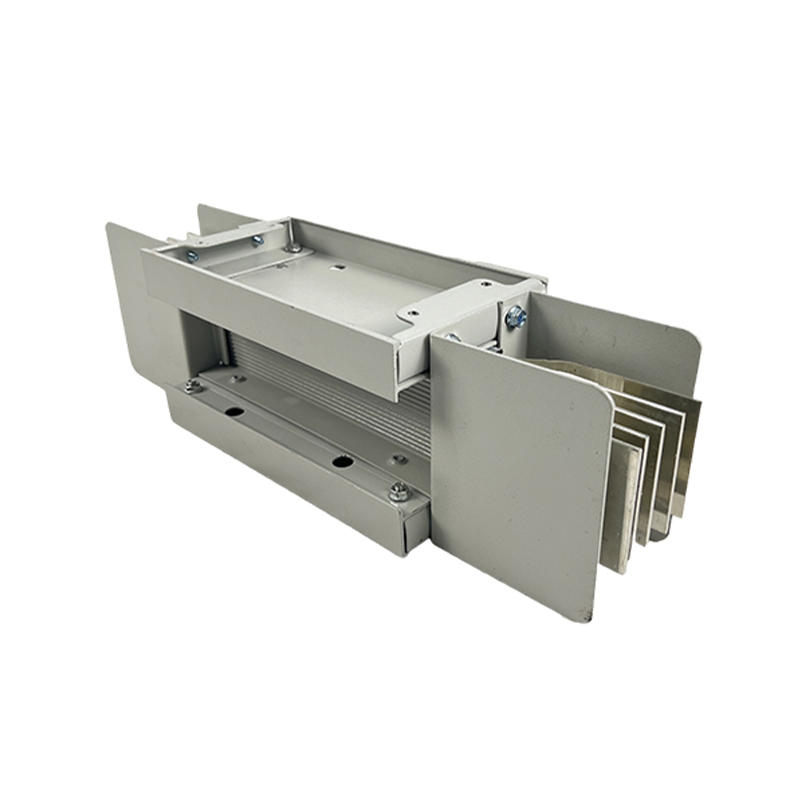

In modern power distribution systems, improving efficiency is a vital goal. As an advanced solution, aluminum electrical compact busbar has demonstrated unique advantages in achieving efficient power distribution. Through its excellent design, material selection and manufacturing process, this busbar not only improves the efficiency of power transmission, but also optimizes the operating performance of the entire system.

First of all, the choice of aluminum material lays the foundation for improving the efficiency of the power distribution system. Aluminum has excellent electrical conductivity. Although its conductivity is slightly lower than that of copper, it is lighter and has lower cost. This means that using aluminum as a busbar material can significantly reduce the overall weight while maintaining good conductivity, making it easier to install and maintain. In addition, the good thermal conductivity of aluminum material helps to quickly dissipate heat and reduce energy loss caused by overheating, thereby further improving power transmission efficiency.

Secondly, the compact design is a highlight of the aluminum electrical compact busbar. Compared with traditional busbars, the compact design occupies less space, which not only saves valuable installation space, but also makes wiring more flexible and convenient. Achieving efficient power transmission in a limited space is particularly important for places such as industrial facilities, commercial buildings and data centers. The compact design also means less mutual interference between cables and pipes, reduces the possibility of energy loss, and improves the overall aesthetics and neatness of the system.

Furthermore, the modular design of the aluminum electrical compact busbar greatly simplifies the installation process. Traditional power distribution systems usually require complex wiring and a lot of on-site construction, while the compact busbar uses prefabricated components and can be installed with simple splicing. This modular structure not only shortens installation time and reduces labor costs, but also reduces the risk of human error. In addition, the modular design makes it easier to expand or modify later. Users can adjust the system configuration at any time according to actual needs without large-scale rewiring, ensuring the flexibility and scalability of the system.

In terms of safety, the aluminum electrical compact busbar also performs well. Its sturdy and durable shell can effectively protect the internal conductors from the influence of the external environment, such as dust, moisture and other contaminants. This protective measure not only extends the service life of the equipment, but also greatly reduces the safety hazards caused by short circuits or other electrical faults. At the same time, the compact design reduces the number of exposed wires, further improving the safety of the working environment.

It is worth mentioning that the performance of the aluminum electrical compact busbar in energy saving and consumption reduction cannot be ignored. Its low impedance characteristics make the power loss less during transmission, ensuring a higher energy efficiency ratio. In addition, due to the use of high-quality insulation materials, this busbar can operate stably in high temperature and high humidity environments, avoiding energy waste caused by increased resistance due to temperature changes. Good heat dissipation performance also helps to maintain a lower operating temperature, thereby reducing the burden on the cooling system and indirectly achieving energy savings.

In the long run, the design concept of the aluminum electrical compact busbar reflects the emphasis on sustainable development. The use of recyclable aluminum not only helps to reduce the carbon footprint of the production process, but also reduces the cost and environmental impact of waste disposal. At the same time, the compact design and modular architecture make the system easier to upgrade and maintain, extend the product life cycle, and promote the effective use of resources.

Finally, the application of the aluminum electrical compact busbar also brings many conveniences to users. For example, its standardized interface design allows seamless docking between products of different brands and models, enhancing the compatibility and interoperability of the system. In addition, this type of busbar is usually equipped with an intelligent monitoring system that can monitor key parameters such as current and voltage in real time, helping users to promptly identify and solve potential problems and ensure that the system is always in optimal operating condition.

In summary, the efficiency of the power distribution system can be significantly improved by using aluminum electrical compact busbar. From material selection to compact design, to modular installation and intelligent management, every link is aimed at optimizing the power transmission process, reducing energy loss, and improving the safety and reliability of the system. With the continuous advancement of technology and changes in market demand, it is believed that aluminum electrical compact busbar will play an important role in more fields and contribute to the construction of an efficient and green distribution network.

First of all, the choice of aluminum material lays the foundation for improving the efficiency of the power distribution system. Aluminum has excellent electrical conductivity. Although its conductivity is slightly lower than that of copper, it is lighter and has lower cost. This means that using aluminum as a busbar material can significantly reduce the overall weight while maintaining good conductivity, making it easier to install and maintain. In addition, the good thermal conductivity of aluminum material helps to quickly dissipate heat and reduce energy loss caused by overheating, thereby further improving power transmission efficiency.

Secondly, the compact design is a highlight of the aluminum electrical compact busbar. Compared with traditional busbars, the compact design occupies less space, which not only saves valuable installation space, but also makes wiring more flexible and convenient. Achieving efficient power transmission in a limited space is particularly important for places such as industrial facilities, commercial buildings and data centers. The compact design also means less mutual interference between cables and pipes, reduces the possibility of energy loss, and improves the overall aesthetics and neatness of the system.

Furthermore, the modular design of the aluminum electrical compact busbar greatly simplifies the installation process. Traditional power distribution systems usually require complex wiring and a lot of on-site construction, while the compact busbar uses prefabricated components and can be installed with simple splicing. This modular structure not only shortens installation time and reduces labor costs, but also reduces the risk of human error. In addition, the modular design makes it easier to expand or modify later. Users can adjust the system configuration at any time according to actual needs without large-scale rewiring, ensuring the flexibility and scalability of the system.

In terms of safety, the aluminum electrical compact busbar also performs well. Its sturdy and durable shell can effectively protect the internal conductors from the influence of the external environment, such as dust, moisture and other contaminants. This protective measure not only extends the service life of the equipment, but also greatly reduces the safety hazards caused by short circuits or other electrical faults. At the same time, the compact design reduces the number of exposed wires, further improving the safety of the working environment.

It is worth mentioning that the performance of the aluminum electrical compact busbar in energy saving and consumption reduction cannot be ignored. Its low impedance characteristics make the power loss less during transmission, ensuring a higher energy efficiency ratio. In addition, due to the use of high-quality insulation materials, this busbar can operate stably in high temperature and high humidity environments, avoiding energy waste caused by increased resistance due to temperature changes. Good heat dissipation performance also helps to maintain a lower operating temperature, thereby reducing the burden on the cooling system and indirectly achieving energy savings.

In the long run, the design concept of the aluminum electrical compact busbar reflects the emphasis on sustainable development. The use of recyclable aluminum not only helps to reduce the carbon footprint of the production process, but also reduces the cost and environmental impact of waste disposal. At the same time, the compact design and modular architecture make the system easier to upgrade and maintain, extend the product life cycle, and promote the effective use of resources.

Finally, the application of the aluminum electrical compact busbar also brings many conveniences to users. For example, its standardized interface design allows seamless docking between products of different brands and models, enhancing the compatibility and interoperability of the system. In addition, this type of busbar is usually equipped with an intelligent monitoring system that can monitor key parameters such as current and voltage in real time, helping users to promptly identify and solve potential problems and ensure that the system is always in optimal operating condition.

In summary, the efficiency of the power distribution system can be significantly improved by using aluminum electrical compact busbar. From material selection to compact design, to modular installation and intelligent management, every link is aimed at optimizing the power transmission process, reducing energy loss, and improving the safety and reliability of the system. With the continuous advancement of technology and changes in market demand, it is believed that aluminum electrical compact busbar will play an important role in more fields and contribute to the construction of an efficient and green distribution network.