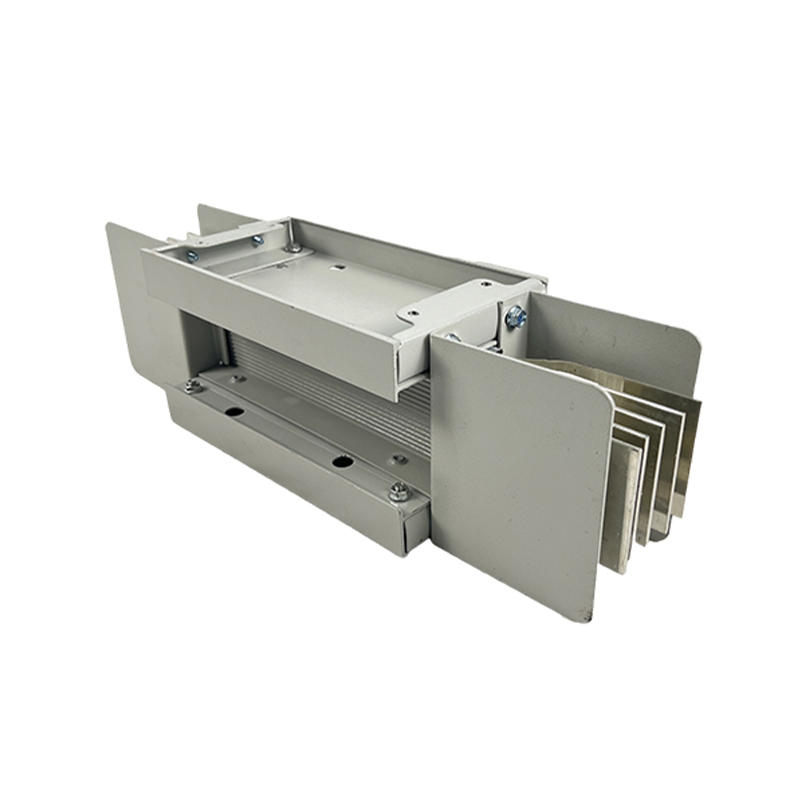

How does the anti-corrosion treatment process of ladder type cable duct affect its service life in outdoor humid environments?

Release Time : 2025-08-18

In humid outdoor environments, the anti-corrosion treatment of ladder-type cable ducts directly impacts their service life. Humid environments contain high levels of moisture, oxygen, and airborne contaminants, which can continuously corrode the metal material of cable ducts. Without effective anti-corrosion protection, the ducts may gradually rust and thin, ultimately compromising their structural strength and protective performance. Anti-corrosion treatments form a protective layer on the cable duct surface or modify the metal surface properties, blocking contact between corrosive media and the substrate, thereby slowing the corrosion process and providing long-term protection for the cable duct in humid environments.

The integrity of the anti-corrosion treatment's protective layer is the first barrier against humid corrosion. A high-quality anti-corrosion treatment creates a continuous, uniform, and dense protective layer on the cable duct surface. This layer effectively isolates moisture, oxygen, and corrosive substances, preventing them from penetrating the metal substrate and causing corrosion. Whether using coatings, plating, or other treatments, uniformity and adhesion are crucial. If there are process defects, such as coating omissions, plating peeling, or pinholes, corrosive media in humid environments can penetrate through these weak spots, causing localized corrosion on the substrate surface. This can then gradually expand, undermining the overall protective effect and shortening the cable tray's service life.

Different anti-corrosion treatments vary in their resistance to various types of corrosion in humid environments. Corrosion in outdoor humid environments encompasses not only simple electrochemical corrosion but also complex conditions caused by environmental salt and industrial pollutants. For example, humid air in coastal areas contains salt, which accelerates metal rust; humid environments in industrial areas may contain acidic or alkaline substances, which chemically attack the protective layer. Targeted anti-corrosion treatments select appropriate protective materials and treatments based on specific environmental characteristics, such as salt spray-resistant coatings and chemical-resistant platings. By enhancing resistance to specific corrosive factors, they ensure the cable tray maintains stable protective performance in complex humid environments.

The aging resistance of the anti-corrosion treatment affects the long-term sustainability of the protective effect. In outdoor environments, factors such as sunlight, temperature fluctuations, and humidity fluctuations can cause the anti-corrosion coating to gradually degrade, resulting in cracking, powdering, and oxidation and discoloration of the plating. A well-designed anti-corrosion treatment process enhances the aging resistance of the protective layer through material selection and process optimization, ensuring that it maintains structural stability under long-term environmental conditions and is less susceptible to aging failure. If the anti-corrosion coating's aging resistance is insufficient, it will deteriorate more quickly in humid environments, losing its protective effect on the base material. This accelerates the corrosion process and causes rust to develop in a shorter period of time, shortening the cable tray's service life.

The coverage of cable tray structural details in the anti-corrosion treatment process is also crucial. Ladder-type cable ducts have structural details such as ladders, connection points, and corners, which are often high-risk areas for corrosion. For example, water easily accumulates around bolts, and the protective layer is easily worn at corners. A sophisticated anti-corrosion treatment process specifically addresses these details to ensure complete coverage of the protective layer, eliminating any gaps or weak links. For example, welding areas should be polished before anti-corrosion treatment, and bolts and other connectors should be treated with the same anti-corrosion process as the trough itself. This prevents the spread of "pitting corrosion" caused by inadequate local protection, ensuring uniform stress distribution throughout the cable trough in humid environments and extending its overall service life.

The bond strength between the anti-corrosion treatment and the base material affects the durability of the protective layer. In humid outdoor environments, cable troughs may be subject to vibration, impact, and thermal expansion and contraction caused by temperature fluctuations. This requires sufficient bond strength between the anti-corrosion layer and the base material to prevent peeling or detachment. Advanced anti-corrosion treatment processes enhance the adhesion between the base material and the protective layer through pre-treatment (such as surface rust removal and roughening). This allows the protective layer to deform with the base material and resist separation due to external forces or environmental changes. If the bond strength is insufficient, the protective layer can easily crack or warp due to slight deformation in humid environments, allowing corrosive media to enter, weakening the anti-corrosion effect and shortening the cable trough's service life.

The anti-corrosion treatment process for ladder-type cable ducts directly impacts their service life in wet outdoor environments by forming a complete protective layer, resisting specific corrosion factors, improving aging resistance, covering structural details, and enhancing bonding strength. A scientific and appropriate anti-corrosion process can effectively slow the corrosion process, ensuring the cable duct's structural integrity and protective performance over long-term use, reducing the need for maintenance and replacement due to corrosion. However, process defects can significantly reduce protective effectiveness, accelerate cable duct damage, and shorten its service life in wet environments. Therefore, selecting the appropriate anti-corrosion treatment process is key to ensuring the long-term and stable operation of ladder-type cable ducts in wet outdoor environments.