How does the aluminum electrical compact busbar achieve lightweight advantages while maintaining excellent conductivity?

Release Time : 2025-09-01

Aluminum electrical compact busbars are playing an increasingly important role in modern power systems, particularly in space-constrained, load-intensive industrial and commercial power distribution scenarios. Their synergistic advantages of lightweight and high conductivity are a key driver in replacing traditional cables and bulky copper busbars. Lightweighting doesn't come at the expense of electrical performance; rather, it achieves a delicate balance between weight and efficiency through the comprehensive optimization of material properties, structural design, and system integration.

As a conductor, aluminum has a much lower density than copper, which is the physical basis for lightweighting. For the same volume, aluminum is significantly lighter, significantly reducing the weight of the entire busbar trunking. This characteristic is particularly prominent in vertical power supply systems in high-rise buildings, long overhead installations, or locations with limited load-bearing structures. Lighter busbar trunking reduces the load on supporting structures, easing installation complexity and civil engineering costs. It also facilitates transportation and on-site handling, improving construction efficiency. Even in industrial environments requiring frequent maintenance and adjustments, the lightweight design makes maintenance more flexible and convenient.

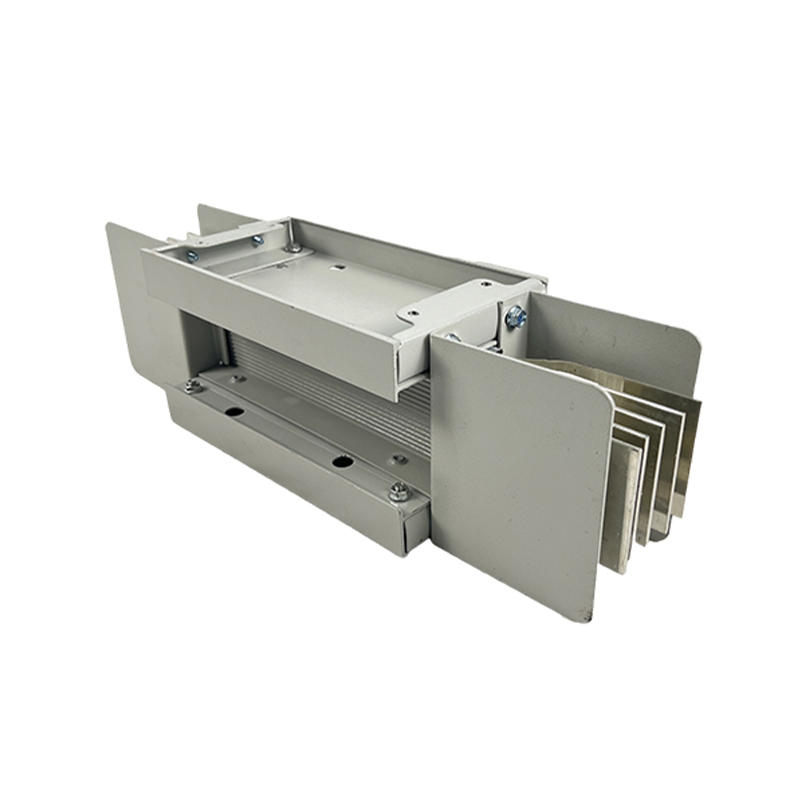

However, lightness doesn't necessarily mean compromising performance. Although aluminum's conductivity is lower than copper, through appropriate cross-sectional design and purity control, it can fully meet the demands of high-current transmission. Modern aluminum busbars utilize high-purity electrolytic aluminum to reduce impurities that hinder electron flow and improve conductivity. Conductor cross-sections are precisely calculated based on current carrying capacity, and while ensuring a safe temperature rise, optimized shape and layout maximize space utilization. The compact busbar design further enhances this advantage: multiple conductors are arranged in parallel, with short phase spacing, and tightly enclosed by a tightly enclosed casing, resulting in an overall volume significantly smaller than traditional cable tray systems. This high level of integration not only saves space but also reduces the spread of external electromagnetic fields, improving the system's electromagnetic compatibility.

Conductor surface treatment technology is also crucial. Aluminum easily forms an oxide film in air, which affects contact performance. Therefore, busbar connections often utilize specialized processes such as tinning, silver plating, or coating with conductive paste to ensure low contact resistance and long-term stability at the plug-in joints. Insulating supports within the casing precisely secure the conductors, preventing displacement caused by electromagnetic forces or vibration during operation and ensuring electrical clearance and creepage distances. These detailed designs ensure smooth current transmission and controlled temperature rise even under sustained high-load operation.

The improved heat dissipation capacity indirectly enhances electrical conductivity. The conductors of the compact busbar are exposed in a closed but ventilated channel, allowing heat to be effectively dissipated through conduction, convection, and radiation. Some designs also employ a corrugated structure or add heat dissipation fins to increase surface area and accelerate heat dissipation. This improved heat dissipation allows the conductors to operate safely at higher currents without overheating or aging, thereby increasing current-carrying capacity without increasing cross-section, further embodying the "light yet strong" design concept.

In addition, modular and standardized production gives aluminum busbar ducting advantages in system integration. Each busbar section is prefabricated in the factory, requiring only bolting or plugging on-site, eliminating on-site cutting and crimping, and avoiding manual construction errors. This industrialized production method not only ensures consistent conductor and insulation quality, but also makes the overall system more compact and reliable.

Ultimately, the aluminum electrical compact busbar achieves both lightweight and high performance through a deep integration of material selection, structural innovation, and manufacturing processes. It's no longer a simple replacement of conductors, but a systematic upgrade to traditional power distribution methods. In the pursuit of efficiency, safety, and sustainability in modern power architecture, it carries enormous currents with its lightweight form, becoming a silent yet resilient energy channel in the pulse of the city.

As a conductor, aluminum has a much lower density than copper, which is the physical basis for lightweighting. For the same volume, aluminum is significantly lighter, significantly reducing the weight of the entire busbar trunking. This characteristic is particularly prominent in vertical power supply systems in high-rise buildings, long overhead installations, or locations with limited load-bearing structures. Lighter busbar trunking reduces the load on supporting structures, easing installation complexity and civil engineering costs. It also facilitates transportation and on-site handling, improving construction efficiency. Even in industrial environments requiring frequent maintenance and adjustments, the lightweight design makes maintenance more flexible and convenient.

However, lightness doesn't necessarily mean compromising performance. Although aluminum's conductivity is lower than copper, through appropriate cross-sectional design and purity control, it can fully meet the demands of high-current transmission. Modern aluminum busbars utilize high-purity electrolytic aluminum to reduce impurities that hinder electron flow and improve conductivity. Conductor cross-sections are precisely calculated based on current carrying capacity, and while ensuring a safe temperature rise, optimized shape and layout maximize space utilization. The compact busbar design further enhances this advantage: multiple conductors are arranged in parallel, with short phase spacing, and tightly enclosed by a tightly enclosed casing, resulting in an overall volume significantly smaller than traditional cable tray systems. This high level of integration not only saves space but also reduces the spread of external electromagnetic fields, improving the system's electromagnetic compatibility.

Conductor surface treatment technology is also crucial. Aluminum easily forms an oxide film in air, which affects contact performance. Therefore, busbar connections often utilize specialized processes such as tinning, silver plating, or coating with conductive paste to ensure low contact resistance and long-term stability at the plug-in joints. Insulating supports within the casing precisely secure the conductors, preventing displacement caused by electromagnetic forces or vibration during operation and ensuring electrical clearance and creepage distances. These detailed designs ensure smooth current transmission and controlled temperature rise even under sustained high-load operation.

The improved heat dissipation capacity indirectly enhances electrical conductivity. The conductors of the compact busbar are exposed in a closed but ventilated channel, allowing heat to be effectively dissipated through conduction, convection, and radiation. Some designs also employ a corrugated structure or add heat dissipation fins to increase surface area and accelerate heat dissipation. This improved heat dissipation allows the conductors to operate safely at higher currents without overheating or aging, thereby increasing current-carrying capacity without increasing cross-section, further embodying the "light yet strong" design concept.

In addition, modular and standardized production gives aluminum busbar ducting advantages in system integration. Each busbar section is prefabricated in the factory, requiring only bolting or plugging on-site, eliminating on-site cutting and crimping, and avoiding manual construction errors. This industrialized production method not only ensures consistent conductor and insulation quality, but also makes the overall system more compact and reliable.

Ultimately, the aluminum electrical compact busbar achieves both lightweight and high performance through a deep integration of material selection, structural innovation, and manufacturing processes. It's no longer a simple replacement of conductors, but a systematic upgrade to traditional power distribution methods. In the pursuit of efficiency, safety, and sustainability in modern power architecture, it carries enormous currents with its lightweight form, becoming a silent yet resilient energy channel in the pulse of the city.