How can ladder-type cable ducts effectively prevent cable bottom crushing or deformation caused by concentrated gravity?

Release Time : 2025-09-29

In complex electrical systems such as modern buildings, industrial plants, data centers, and rail transit, cable installation safety and long-term reliability are crucial. Traditional closed or rectangular cable trays, when carrying large numbers of cables, often face excessive concentrated pressure at the bottom due to structural design limitations. This is particularly true in long-span, multi-layer stacking, or large-section cable routing scenarios. These cables are prone to insulation dents, sheath deformation, and even conductor damage, creating short circuit, leakage, or fire hazards. To address this challenge, ladder-type cable ducts, with their unique structural design, are an ideal solution for optimizing cable stress distribution and preventing crushing and deformation.

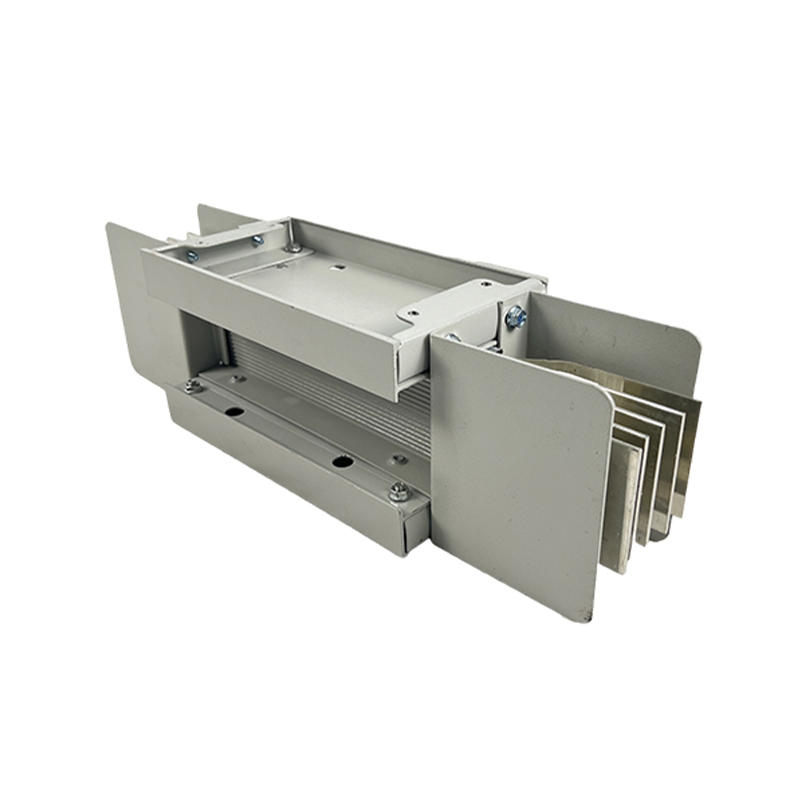

1. Ladder-shaped structure achieves efficient force distribution

The core advantage of ladder-type cable ducts lies in their open, ladder-shaped cross-section: consisting of two parallel side longitudinal beams and evenly spaced cross braces, the overall profile is wide at the top and narrow at the bottom. When cables are laid within them, their weight is not concentrated in a single plane, but instead supported in sections by multiple cross braces. Each cross brace acts as an independent load-bearing point, evenly transferring the cable's deadweight to the longitudinal beams on either side, and from there to the support system. This "lattice-like" support effectively avoids the "indentation effect" caused by the continuous contact of the cable with the bottom surface in traditional closed troughs. It is particularly effective in protecting large-diameter power cables or multi-core control cables.

2. Optimized cross brace spacing increases support density

The cross brace spacing for ladder-type cable ducts is typically designed to be 200mm–300mm, significantly smaller than the cable's natural bend radius. This spacing ensures that the cable is consistently supported at multiple points along its entire length, preventing sagging and localized stress concentration caused by excessive spans. For heavy cables or high-density wiring, denser or double-layered cross braces can be used to further increase support density and prevent the cable from "bridging" between cross braces under its own weight, causing compression and deformation in the middle.

3. Side Stringers Enhance Overall Rigidity and Bending Resistance

The side stringers of ladder-type cable ducts are typically constructed of thickened steel plates or aluminum alloy profiles, precision-bent and reinforced with ribs, resulting in excellent bending and torsional resistance. During long-span installations, the stringers effectively resist bending stress caused by the total weight of the cables, maintaining the overall straightness of the trough and preventing additional pressure on the cables underneath due to trough sagging. Furthermore, the high-strength design of the stringers reduces the number of intermediate support points, reducing installation costs while maintaining a flat cable layout.

4. Open Design Avoids the "Stacking Effect"

In traditional closed cable trays, when multiple layers of cables are stacked, the weight of the upper cables is transferred layer by layer to the lower layers, creating a "stacking effect" that places significant pressure on the lower cables. The open structure of ladder-type cable ducts, however, allows the cables to be laid naturally, forming a slight arc. A certain amount of space between cables is maintained to minimize direct contact and compression. At the same time, maintenance personnel can clearly observe the cable arrangement, avoiding overcrowding and ensuring that each cable has adequate space. This prevents sheath deformation and poor heat dissipation caused by crowding.

5. Materials and Surface Treatment Enhance Durability

Ladder-type cable ducts are typically made of cold-rolled steel, hot-dip galvanized, aluminum alloy, or fiberglass, offering excellent corrosion resistance and mechanical strength. The galvanizing layer not only protects against corrosion but also enhances surface hardness, preventing the cross brace edges from scratching the cable sheath. Some high-end products feature rubber pads or flexible edging on the top of the cross braces to further cushion contact pressure and protect the cable sheath from mechanical damage.

6. Scientific Wiring Standards and Installation Guidelines

To maximize the crush-proof performance of ladder-type cable ducts, adhere to the principle of a "cable fill ratio no more than 50%" during installation and allow ample space. Furthermore, cables of different specifications should be laid in separate layers, with larger cables placed on the bottom layer and smaller cables on the top layer to avoid "small cables supporting larger cables." Special elbows should be installed at bends to ensure the bending radius meets standards and prevent excessive local stress.

Ladder-type cable duct, with its scientifically designed trapezoidal structure, multi-point support braces, high-strength longitudinal beams, and open layout, fundamentally changes the cable's stress pattern, transforming concentrated pressure into evenly distributed support. This effectively prevents cable crushing, deformation, and insulation degradation caused by concentrated gravity. It serves not only as a "transport channel" for cables but also as their protective armor. In today's pursuit of safe, reliable, and long-lasting electrical systems, ladder-type cable duct has become an indispensable key component in modern structured cabling systems.

1. Ladder-shaped structure achieves efficient force distribution

The core advantage of ladder-type cable ducts lies in their open, ladder-shaped cross-section: consisting of two parallel side longitudinal beams and evenly spaced cross braces, the overall profile is wide at the top and narrow at the bottom. When cables are laid within them, their weight is not concentrated in a single plane, but instead supported in sections by multiple cross braces. Each cross brace acts as an independent load-bearing point, evenly transferring the cable's deadweight to the longitudinal beams on either side, and from there to the support system. This "lattice-like" support effectively avoids the "indentation effect" caused by the continuous contact of the cable with the bottom surface in traditional closed troughs. It is particularly effective in protecting large-diameter power cables or multi-core control cables.

2. Optimized cross brace spacing increases support density

The cross brace spacing for ladder-type cable ducts is typically designed to be 200mm–300mm, significantly smaller than the cable's natural bend radius. This spacing ensures that the cable is consistently supported at multiple points along its entire length, preventing sagging and localized stress concentration caused by excessive spans. For heavy cables or high-density wiring, denser or double-layered cross braces can be used to further increase support density and prevent the cable from "bridging" between cross braces under its own weight, causing compression and deformation in the middle.

3. Side Stringers Enhance Overall Rigidity and Bending Resistance

The side stringers of ladder-type cable ducts are typically constructed of thickened steel plates or aluminum alloy profiles, precision-bent and reinforced with ribs, resulting in excellent bending and torsional resistance. During long-span installations, the stringers effectively resist bending stress caused by the total weight of the cables, maintaining the overall straightness of the trough and preventing additional pressure on the cables underneath due to trough sagging. Furthermore, the high-strength design of the stringers reduces the number of intermediate support points, reducing installation costs while maintaining a flat cable layout.

4. Open Design Avoids the "Stacking Effect"

In traditional closed cable trays, when multiple layers of cables are stacked, the weight of the upper cables is transferred layer by layer to the lower layers, creating a "stacking effect" that places significant pressure on the lower cables. The open structure of ladder-type cable ducts, however, allows the cables to be laid naturally, forming a slight arc. A certain amount of space between cables is maintained to minimize direct contact and compression. At the same time, maintenance personnel can clearly observe the cable arrangement, avoiding overcrowding and ensuring that each cable has adequate space. This prevents sheath deformation and poor heat dissipation caused by crowding.

5. Materials and Surface Treatment Enhance Durability

Ladder-type cable ducts are typically made of cold-rolled steel, hot-dip galvanized, aluminum alloy, or fiberglass, offering excellent corrosion resistance and mechanical strength. The galvanizing layer not only protects against corrosion but also enhances surface hardness, preventing the cross brace edges from scratching the cable sheath. Some high-end products feature rubber pads or flexible edging on the top of the cross braces to further cushion contact pressure and protect the cable sheath from mechanical damage.

6. Scientific Wiring Standards and Installation Guidelines

To maximize the crush-proof performance of ladder-type cable ducts, adhere to the principle of a "cable fill ratio no more than 50%" during installation and allow ample space. Furthermore, cables of different specifications should be laid in separate layers, with larger cables placed on the bottom layer and smaller cables on the top layer to avoid "small cables supporting larger cables." Special elbows should be installed at bends to ensure the bending radius meets standards and prevent excessive local stress.

Ladder-type cable duct, with its scientifically designed trapezoidal structure, multi-point support braces, high-strength longitudinal beams, and open layout, fundamentally changes the cable's stress pattern, transforming concentrated pressure into evenly distributed support. This effectively prevents cable crushing, deformation, and insulation degradation caused by concentrated gravity. It serves not only as a "transport channel" for cables but also as their protective armor. In today's pursuit of safe, reliable, and long-lasting electrical systems, ladder-type cable duct has become an indispensable key component in modern structured cabling systems.