Why must outdoor cable trunking utilize both galvanized steel and powder coating?

Release Time : 2025-09-15

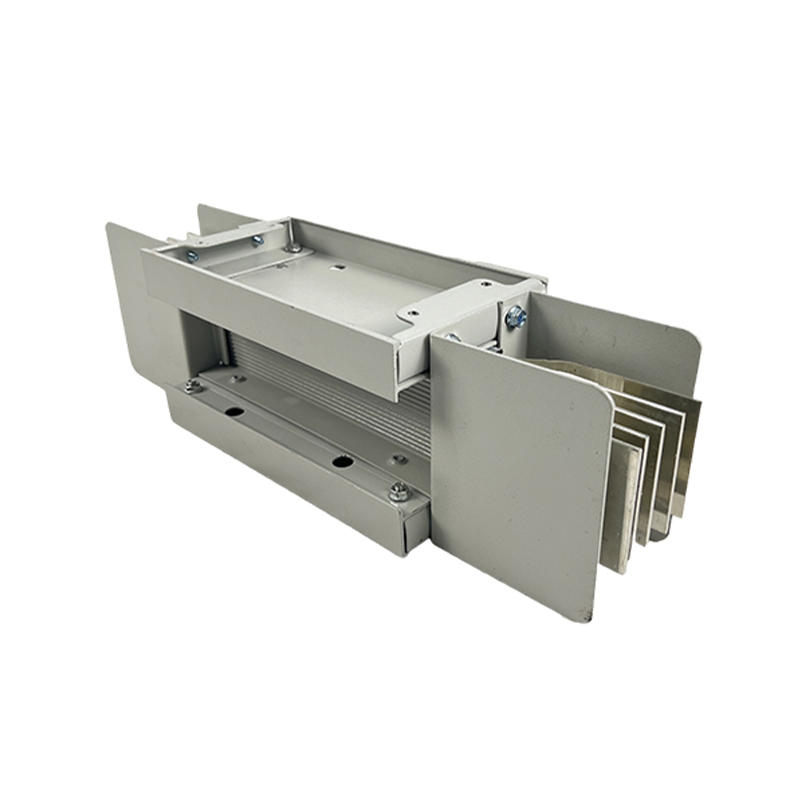

In outdoor power and communications systems, cable trunking plays a crucial role in guiding, protecting, and managing cables. Exposed to the elements, such as sun, rain, wind, sand, salt spray, and industrial pollution, cable trunking endures multiple challenges, including UV radiation, temperature fluctuations, moisture penetration, and chemical corrosion. If insufficiently protected, rust on the metal trunking will not only affect its appearance but also weaken its structural strength, reducing its load-bearing capacity and even leading to safety hazards such as breakage or separation. More seriously, rust products can penetrate the cable sheath, accelerating insulation degradation and threatening the stable operation of the entire power or signal system. Therefore, relying solely on a single protective measure is insufficient to cope with the complex and ever-changing conditions of outdoor operation. A more comprehensive, combined protection strategy is essential—the combination of galvanized steel and powder coating is precisely what was developed for this purpose.

As the primary protective layer, galvanized steel's core lies in the electrochemical protection mechanism of the "sacrificial anode." A zinc layer coats the steel surface. When moisture and oxygen in the environment react, the zinc oxidizes before the iron, forming a dense protective film of basic zinc carbonate that prevents corrosion from spreading to the underlying steel. Even if the tank is slightly scratched during transportation or installation, exposing a small amount of the base material, the surrounding zinc continues to provide cathodic protection, preventing rust from spreading through the wound. This "active defense" property makes the zinc coating a solid first line of defense against incipient corrosion.

However, zinc coating is not a panacea. In environments with strong acids, bases, or salts, zinc consumption accelerates, and long-term exposure may result in white rust or localized penetration. Furthermore, pure zinc coatings are susceptible to oxidation and discoloration under strong ultraviolet light, affecting appearance and failing to completely block direct contact with moisture and contaminants. This is where powder coating becomes a crucial "second layer of insurance."

Powder coating is an organic protective layer applied electrostatically and then cured at high temperatures. It evenly coats the galvanized steel surface, forming a continuous, dense, and seamless physical barrier. It completely isolates the metal from the external environment, effectively blocking the intrusion of rain, moisture, oil, chemicals, and dust. High-quality coatings offer excellent weather resistance, withstanding UV exposure for long periods without chalking or cracking, maintaining stable color and structural integrity. Furthermore, the coating's smooth surface resists dust accumulation, making it easy to clean and maintain, further extending its service life.

More importantly, the galvanizing and powder coating are not simply superimposed; rather, they enhance each other's effectiveness. The galvanizing provides a smooth, clean, and highly adhesive base for the powder coating, ensuring secure adhesion; while the powder coating protects the zinc layer from rapid wear and tear, extending its electrochemical protection period. Together, they form a complete "internal protection, external seal" system: the zinc layer continuously inhibits electrochemical corrosion at the microscopic level, while the powder coating blocks macroscopic environmental erosion at the macroscopic level, forming a long-term, stable closed-loop protection loop.

In actual engineering, this dual protection is also reflected in the detailed treatment. Connectors, elbows, brackets, and other parts undergo the same treatment process to prevent overall failure due to local weaknesses. Even if minor damage occurs during installation, the coating's edge coverage and zinc's self-healing ability minimize the extent of the damage.

When a cable trunking withstands ten years of wind and corrosion at seaside, and remains uncorrupted in the acid rain of a factory, it's not just a triumph of material choice; it's a triumph of protective philosophy. The combination of galvanized steel and powder coating isn't a quick fix; it reflects a profound understanding of time and the environment. It demonstrates, through scientific methods, that true durability lies not in a momentary sturdiness but in a systematic, layered, and meticulously implemented approach.

As the primary protective layer, galvanized steel's core lies in the electrochemical protection mechanism of the "sacrificial anode." A zinc layer coats the steel surface. When moisture and oxygen in the environment react, the zinc oxidizes before the iron, forming a dense protective film of basic zinc carbonate that prevents corrosion from spreading to the underlying steel. Even if the tank is slightly scratched during transportation or installation, exposing a small amount of the base material, the surrounding zinc continues to provide cathodic protection, preventing rust from spreading through the wound. This "active defense" property makes the zinc coating a solid first line of defense against incipient corrosion.

However, zinc coating is not a panacea. In environments with strong acids, bases, or salts, zinc consumption accelerates, and long-term exposure may result in white rust or localized penetration. Furthermore, pure zinc coatings are susceptible to oxidation and discoloration under strong ultraviolet light, affecting appearance and failing to completely block direct contact with moisture and contaminants. This is where powder coating becomes a crucial "second layer of insurance."

Powder coating is an organic protective layer applied electrostatically and then cured at high temperatures. It evenly coats the galvanized steel surface, forming a continuous, dense, and seamless physical barrier. It completely isolates the metal from the external environment, effectively blocking the intrusion of rain, moisture, oil, chemicals, and dust. High-quality coatings offer excellent weather resistance, withstanding UV exposure for long periods without chalking or cracking, maintaining stable color and structural integrity. Furthermore, the coating's smooth surface resists dust accumulation, making it easy to clean and maintain, further extending its service life.

More importantly, the galvanizing and powder coating are not simply superimposed; rather, they enhance each other's effectiveness. The galvanizing provides a smooth, clean, and highly adhesive base for the powder coating, ensuring secure adhesion; while the powder coating protects the zinc layer from rapid wear and tear, extending its electrochemical protection period. Together, they form a complete "internal protection, external seal" system: the zinc layer continuously inhibits electrochemical corrosion at the microscopic level, while the powder coating blocks macroscopic environmental erosion at the macroscopic level, forming a long-term, stable closed-loop protection loop.

In actual engineering, this dual protection is also reflected in the detailed treatment. Connectors, elbows, brackets, and other parts undergo the same treatment process to prevent overall failure due to local weaknesses. Even if minor damage occurs during installation, the coating's edge coverage and zinc's self-healing ability minimize the extent of the damage.

When a cable trunking withstands ten years of wind and corrosion at seaside, and remains uncorrupted in the acid rain of a factory, it's not just a triumph of material choice; it's a triumph of protective philosophy. The combination of galvanized steel and powder coating isn't a quick fix; it reflects a profound understanding of time and the environment. It demonstrates, through scientific methods, that true durability lies not in a momentary sturdiness but in a systematic, layered, and meticulously implemented approach.