How does the aluminum electrical compact busbar achieve the miracle of low-resistance and high-efficiency power transmission in a compact structure?

Release Time : 2025-10-27

In modern power systems, industrial power distribution, data centers, rail transit, and new energy equipment, space utilization and power transmission efficiency have become crucial indicators of electrical system advancement. Traditional cable wiring methods, due to limitations such as large space requirements, poor heat dissipation, and complex installation, are no longer able to meet the demands of high-density, high-power scenarios. The aluminum electrical compact busbar, with its exceptional performance of "small size, high current, and low loss," achieves the miracle of "low-resistance and high-efficiency" power transmission within limited spaces, becoming a key solution in modern electrical engineering.

1. Compact Structure: A Revolutionary Breakthrough in Space Utilization

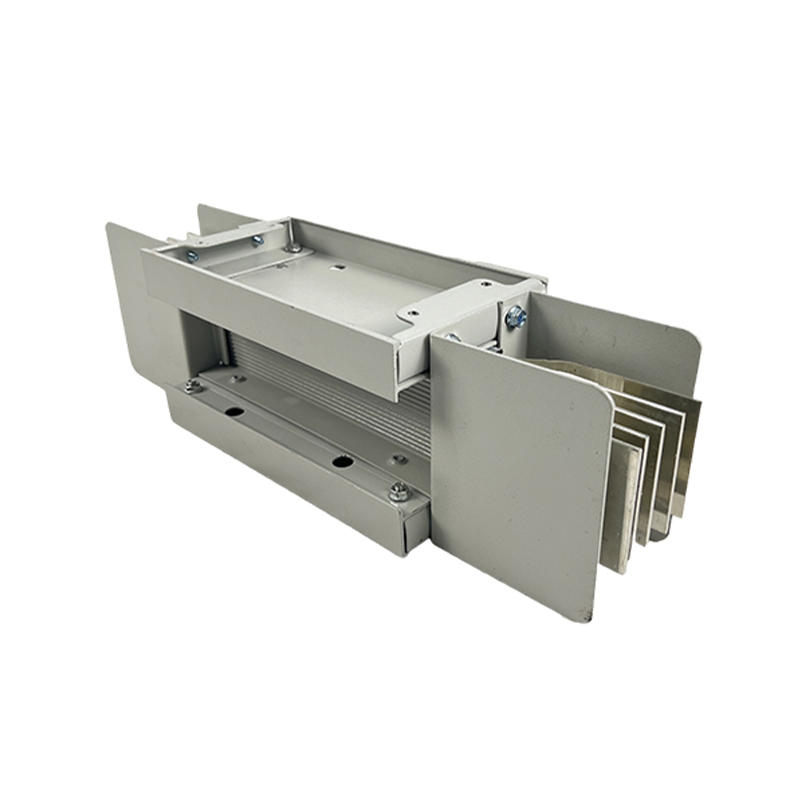

The aluminum electrical compact busbar utilizes a modular design, integrating multiple high-purity aluminum conductors with high-strength insulation and a sophisticated support structure within a compact metal casing, creating a "sandwich" or "stacked" structure. Compared to traditional cables that require extensive wiring troughs, bridges, and bend radii, the busbar system can be installed close to equipment or walls, significantly saving valuable space within buildings or equipment. Compact busbars are particularly suitable for highly integrated electrical cabinets such as power distribution cabinets, inverters, and UPS power supplies, enabling flexible placement and adapting to complex installation environments, significantly improving the overall system's integration and aesthetics.

2. Low-Resistance Design: Ensuring Efficient Power Transmission

Although aluminum's conductivity is approximately 61% that of copper, through optimized cross-sectional design, improved conductor purity, and increased effective cross-sectional area, aluminum busbars can achieve comparable current carrying capacity to copper cables. More importantly, the compact busbars utilize a large contact surface and short paths, reducing the number of joints and contact resistance. The connection between the plug-in box and the trunk line utilizes elastic crimping or double-sided contact technology, ensuring extremely low contact resistance, significantly reducing Joule heating losses during operation. Measured data shows that, at equivalent current carrying capacity, the compact aluminum busbars achieve over 20% lower energy losses than traditional cable systems, truly achieving "low resistance and high efficiency."

3. Excellent Heat Dissipation: Supporting Continuous High-Load Operation

Efficient power transmission requires excellent heat dissipation. The metal casing of the compact busbars not only provides mechanical protection but also serves as a heat sink. A thermal channel is created between the aluminum conductor and the insulation layer, allowing heat to be quickly transferred to the outside air through the casing. Some high-end products also feature forced air cooling or heat sink fins to further improve heat dissipation efficiency. The uniform temperature rise across the busbar prevents insulation aging caused by localized overheating in the cable. It offers long-term stable operation at rated current and supports continuous operating temperatures up to 95°C, making it suitable for high-load industrial scenarios.

4. Electromagnetic Compatibility Optimization: Reduces Interference and Improves System Stability

Electromagnetic interference (EMI) is a potential risk to system stability in a compact design. The aluminum electrical compact busbar effectively counteracts magnetic field radiation through optimized phase sequence and a metal shielded casing. The symmetrical arrangement of the three-phase conductors balances mutual inductance, significantly reducing external magnetic field strength. The fully enclosed metal casing acts as a Faraday cage, preventing electromagnetic waves from escaping and shielding against external interference, ensuring the normal operation of nearby sensitive electronic equipment. This feature makes it widely used in data centers, medical equipment, and automated control systems.

5. Modularity and Ease of Maintenance: Improving System Flexibility and Reliability

The compact busbar utilizes standard modular lengths, allowing for flexible splicing based on actual needs. Plug-in boxes can be installed at any location, enabling "plug-and-play" power distribution. When loads change or equipment upgrades occur, capacity expansion can be achieved by simply adding or removing plug-in units, eliminating the need for rewiring. This significantly shortens construction cycles and reduces operation and maintenance costs. Furthermore, all connection points are within easy visual range, facilitating inspection and troubleshooting, enhancing the maintainability and reliability of the entire distribution system.

The aluminum electrical compact busbar's ability to achieve low-resistance and high-efficiency power transmission in a confined space is the result of comprehensive innovations in materials science, structural design, thermal management, and electromagnetic compatibility. It not only overcomes the bottlenecks of traditional cables in high-density applications, but also, with its energy-saving, safe, and flexible advantages, promotes the development of intelligent and modular electrical systems.

1. Compact Structure: A Revolutionary Breakthrough in Space Utilization

The aluminum electrical compact busbar utilizes a modular design, integrating multiple high-purity aluminum conductors with high-strength insulation and a sophisticated support structure within a compact metal casing, creating a "sandwich" or "stacked" structure. Compared to traditional cables that require extensive wiring troughs, bridges, and bend radii, the busbar system can be installed close to equipment or walls, significantly saving valuable space within buildings or equipment. Compact busbars are particularly suitable for highly integrated electrical cabinets such as power distribution cabinets, inverters, and UPS power supplies, enabling flexible placement and adapting to complex installation environments, significantly improving the overall system's integration and aesthetics.

2. Low-Resistance Design: Ensuring Efficient Power Transmission

Although aluminum's conductivity is approximately 61% that of copper, through optimized cross-sectional design, improved conductor purity, and increased effective cross-sectional area, aluminum busbars can achieve comparable current carrying capacity to copper cables. More importantly, the compact busbars utilize a large contact surface and short paths, reducing the number of joints and contact resistance. The connection between the plug-in box and the trunk line utilizes elastic crimping or double-sided contact technology, ensuring extremely low contact resistance, significantly reducing Joule heating losses during operation. Measured data shows that, at equivalent current carrying capacity, the compact aluminum busbars achieve over 20% lower energy losses than traditional cable systems, truly achieving "low resistance and high efficiency."

3. Excellent Heat Dissipation: Supporting Continuous High-Load Operation

Efficient power transmission requires excellent heat dissipation. The metal casing of the compact busbars not only provides mechanical protection but also serves as a heat sink. A thermal channel is created between the aluminum conductor and the insulation layer, allowing heat to be quickly transferred to the outside air through the casing. Some high-end products also feature forced air cooling or heat sink fins to further improve heat dissipation efficiency. The uniform temperature rise across the busbar prevents insulation aging caused by localized overheating in the cable. It offers long-term stable operation at rated current and supports continuous operating temperatures up to 95°C, making it suitable for high-load industrial scenarios.

4. Electromagnetic Compatibility Optimization: Reduces Interference and Improves System Stability

Electromagnetic interference (EMI) is a potential risk to system stability in a compact design. The aluminum electrical compact busbar effectively counteracts magnetic field radiation through optimized phase sequence and a metal shielded casing. The symmetrical arrangement of the three-phase conductors balances mutual inductance, significantly reducing external magnetic field strength. The fully enclosed metal casing acts as a Faraday cage, preventing electromagnetic waves from escaping and shielding against external interference, ensuring the normal operation of nearby sensitive electronic equipment. This feature makes it widely used in data centers, medical equipment, and automated control systems.

5. Modularity and Ease of Maintenance: Improving System Flexibility and Reliability

The compact busbar utilizes standard modular lengths, allowing for flexible splicing based on actual needs. Plug-in boxes can be installed at any location, enabling "plug-and-play" power distribution. When loads change or equipment upgrades occur, capacity expansion can be achieved by simply adding or removing plug-in units, eliminating the need for rewiring. This significantly shortens construction cycles and reduces operation and maintenance costs. Furthermore, all connection points are within easy visual range, facilitating inspection and troubleshooting, enhancing the maintainability and reliability of the entire distribution system.

The aluminum electrical compact busbar's ability to achieve low-resistance and high-efficiency power transmission in a confined space is the result of comprehensive innovations in materials science, structural design, thermal management, and electromagnetic compatibility. It not only overcomes the bottlenecks of traditional cables in high-density applications, but also, with its energy-saving, safe, and flexible advantages, promotes the development of intelligent and modular electrical systems.